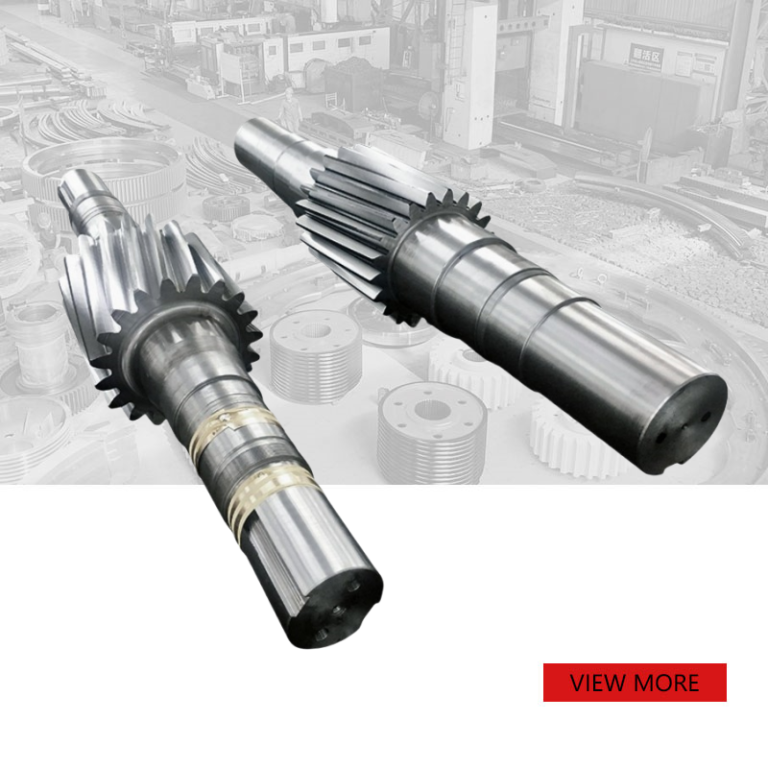

Custom Universal Spindle forged 34CrNiMo6 steel mill connecting shaft

PRODUCT PARAMETERS

Description

.jpg)

Forging: The finished connecting shaft weighs 25 tons and is forged using a 12,000-ton press. The forging is tempered to eliminate the internal stress generated during the forging process, making the forging structure more uniform and dense, and refining the grains to improve the toughness of the material.

Flaw detection: rough flaw detection JB/T5000.15-2007 level Ⅲ

Rough turning: The size must have enough margin, we make rough machining drawings specifically for rough machining

Flaw Detection: After rough turning, we will perform flaw detection to ensure that these problems are identified and dealt with before entering more refined processing steps to avoid wasting more material and time.

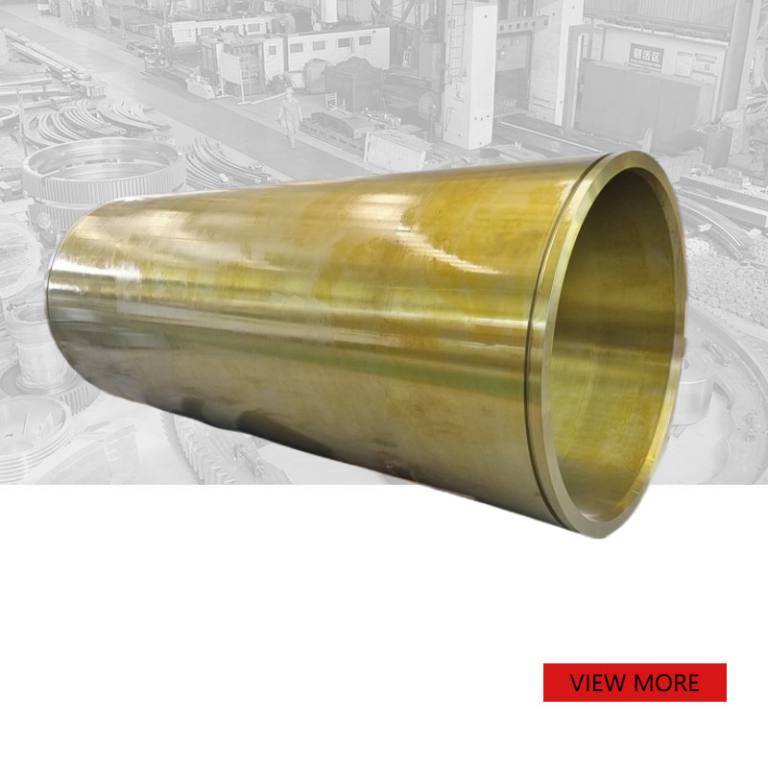

Rough boring: Rough boring of the arc mouth to meet the internal performance requirements of the hot-processed arc mouth.

Heat treatment: We will conduct hardness testing and issue hardness reports and heat treatment curve reports.

Boring machine processing: taking samples.

Mechanical properties: Mechanical properties test report.

Semi-finishing: Further reduce the dimensional error of the connecting shaft, make the connecting shaft closer to the final design size, and improve the surface roughness to prepare for subsequent finishing.

Flaw detection: In order to strictly control the quality standard of the connecting shaft, we once again conducted flaw detection after fine processing.

Boring and milling: Boring the arc mouth, pay attention to prevent the outer circle from being deformed.

Finishing: arc position for tooling, machining center hole position.

Shaft diameter protection: protect the middle shaft diameter to prevent collision during lifting.

Fine boring and milling: Fine boring and milling of arcs at both ends, drilling of oil holes, center of arcs at both ends, machine tool inspection axis deviation ≤ 0.1mm.