Shaft

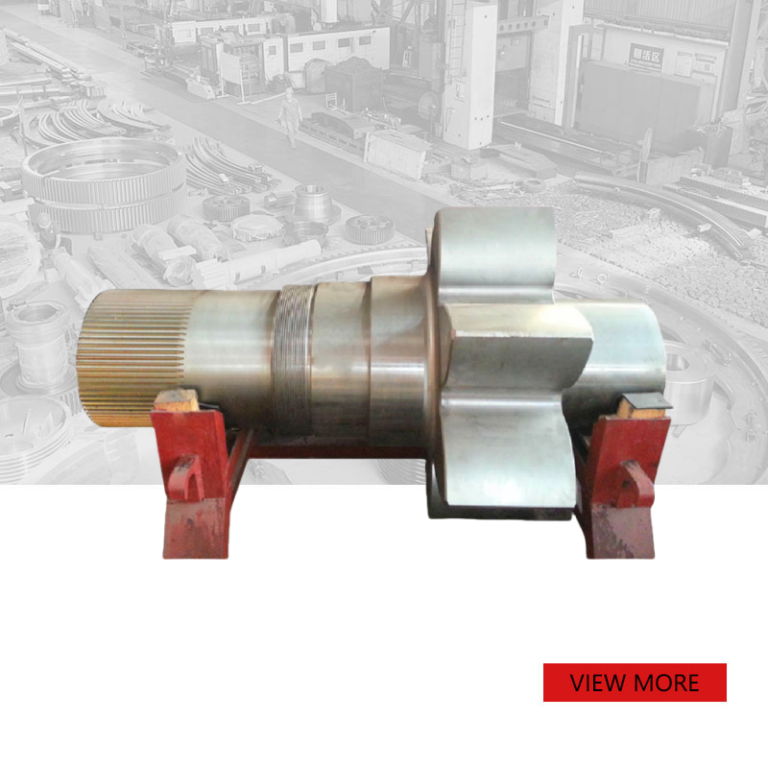

Custom Universal Spindle forged 34CrNiMo6 steel mill connecting shaft

Custom Forged 42CrMo Non-standard Gear Shaft

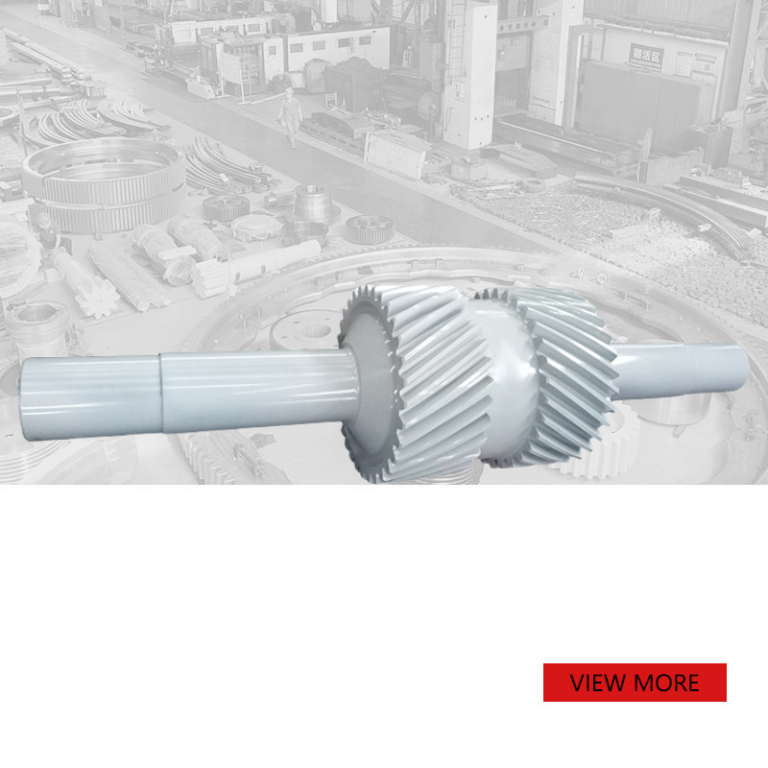

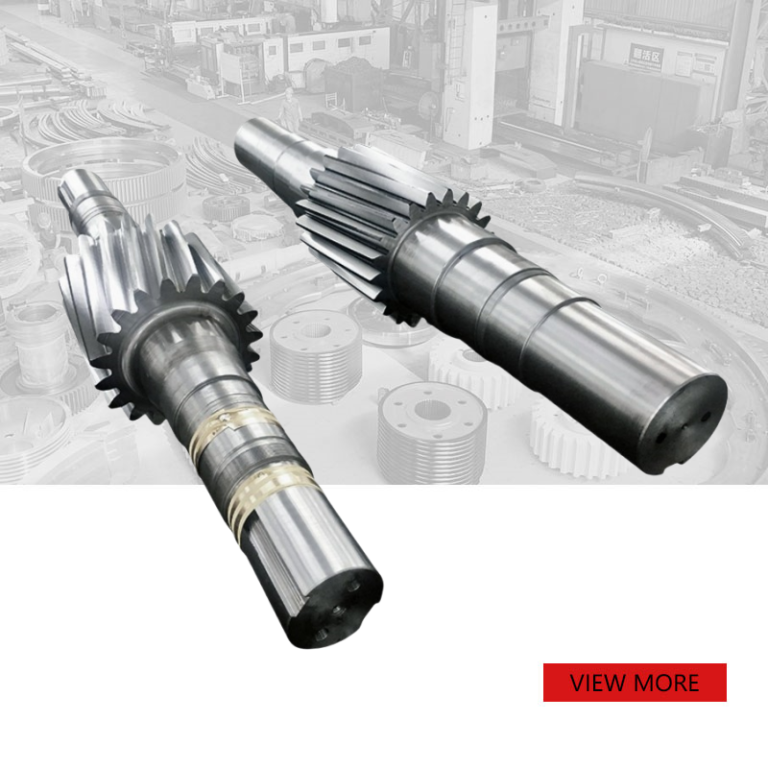

Non-standard alloy steel large Double helical gear shaft with cutting groove

Spur gear shaft forging high quality large diameter for Ball Mill

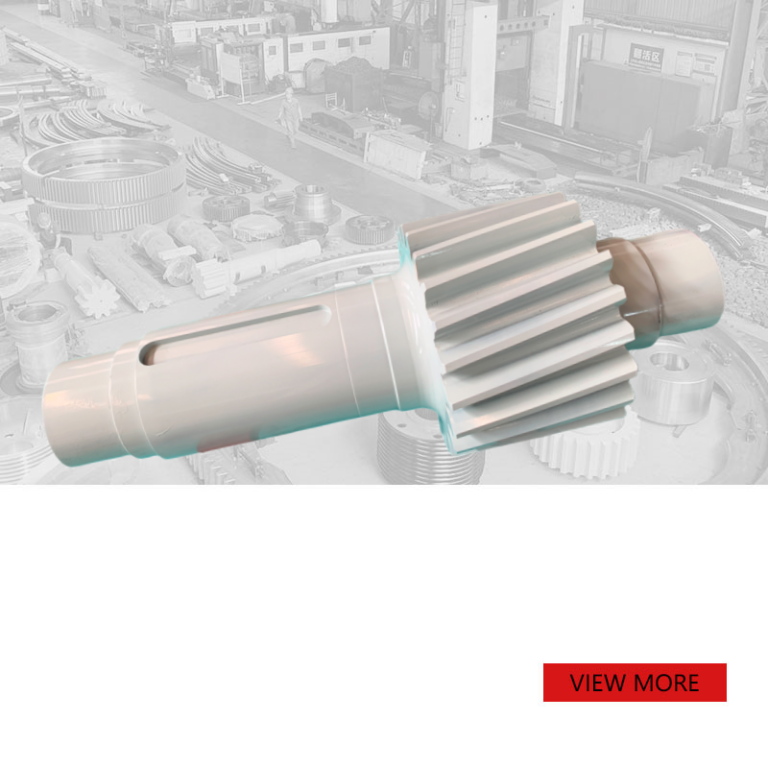

Custom mining forging long helical gear shaft

Large dimater wear-resistant forging Scraper conveyer sprocket shaft

Custom High Quality 42CrMo Forged Steel Pinion Shaft

Spur gear shaft forging high quality large diameter surface quenched

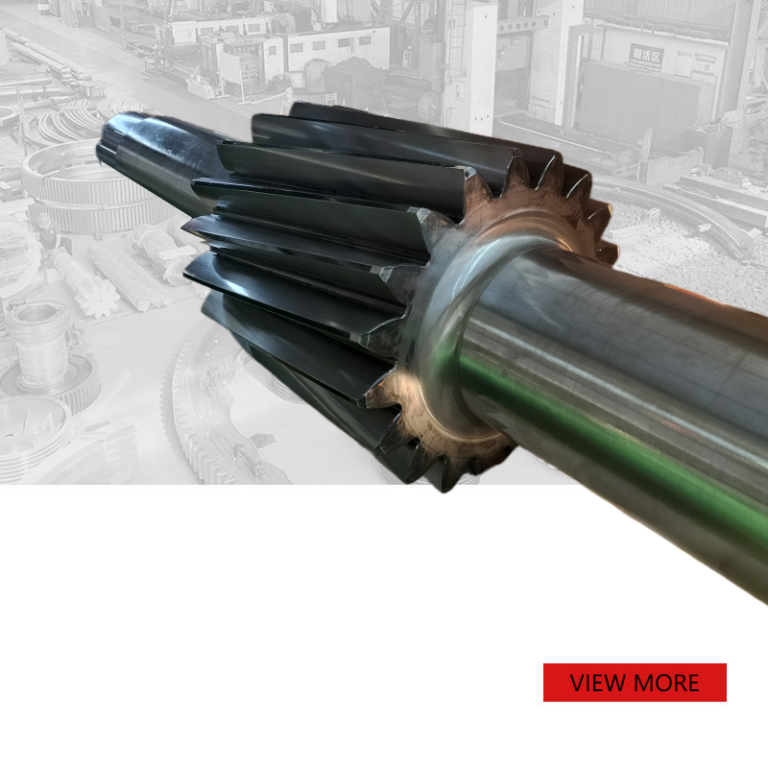

4340 OEM Big Pinion Shaft Spur Toothed Forging Carbon Steel Spur Large Module Gear Shaft

Mining Forging 34XH3M large module spur gear shaft

Mining custom forging large module helical gear shaft

Custom Mining Crusher large heavy main cone shaft

Overview of Shaft

The shaft is one of the most important basic components in mechanical design. It is mainly used to support rotating parts (such as gears, etc.) and transmit motion and power. It is widely used in various mechanical equipment. The shaft can be divided into many types. According to the shape, it can be divided into straight shaft and crankshaft. According to the load condition, it can be divided into spindle, rotating shaft and transmission shaft. According to the manufacturing method, it can be divided into solid shaft and hollow shaft.

Features of Shaft

- Materials and Manufacturing

Material Selection: Shafts are usually made of high-strength metal materials, such as carbon steel, alloy steel, etc., to ensure sufficient strength and durability. In some special environments, stainless steel or aluminum alloys may also be used.

Heat Treatment: In order to improve hardness, wear resistance and fatigue resistance, shafts often undergo heat treatment processes, such as quenching and tempering. - Geometry and Size

Diameter and Length: The diameter and length of the shaft directly affect its load-bearing capacity and stiffness. Depending on the application requirements, the shaft can be designed with different diameters and lengths.

Stepped Shaft: Many shafts are designed in a stepped shape to facilitate the assembly of parts of different sizes and provide better positioning support.

Solid vs. Hollow: Solid shafts are used in most application scenarios, while hollow shafts are suitable for high-speed rotating equipment due to their light weight and low inertia. - Load Capacity

Load Type: Shafts not only have to withstand torque (torque), but may also need to withstand multiple load forms such as bending moment, tension or pressure.

Stress analysis: The maximum stress point should be considered during design to ensure that the shaft will not be excessively deformed or broken under working conditions. - Precision and surface quality

Processing accuracy: For applications with high precision requirements, the processing accuracy of the shaft is very important, including dimensional tolerance, form and position tolerance, etc.

Surface roughness: Good surface finish helps reduce friction and wear and extend service life. - Lubrication and sealing

Lubrication: Proper lubrication is essential to reduce friction between the shaft and bearings or other mating parts.

Sealing measures: Prevent dust, moisture and other contaminants from entering and protect the shaft from damage. - Dynamic balance

For high-speed shafts, dynamic balancing must be performed to reduce vibration and noise and ensure smooth operation. - Maintenance and care

Regularly checking the status of the shaft and performing necessary cleaning and lubrication are the key to ensuring its long-term stable operation. - Application environment adaptability

The design of the shaft also needs to consider factors such as temperature changes, humidity, corrosion, etc. in its working environment, and select appropriate materials and protective measures.

Applications of Shaft

The shaft is mainly used in mining machinery and equipment

Conveying system:

Belt conveyor, scraper conveyor

Crushing equipment:

Jaw crusher, cone crusher

Grinding equipment:

Ball mill, vertical mill

Lifting equipment: bucket elevator, shaft lifting system

Screening equipment: vibrating screen

Drilling equipment

Company profile

Established in 2002, Luoyang Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2015.

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel

making/ forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are looking for high quality shaft products, please feel free to contact us.(sales@citicwl.com)

FAQs of Shaft

What materials are commonly used to manufacture shafts?

Shafts are typically made from steel or alloy due to their strength and durability.

Can shafts be customized for specific applications?

Yes, shafts can be engineered in various dimensions and shapes to meet specific operational needs.

How do you maintain the longevity of a shaft?

Regular maintenance, proper lubrication, and surface treatments like galvanization help extend a shaft's lifespan.

Are there international standards for shaft production?

Yes, ISO standards define the tolerances and specifications for shaft production globally.