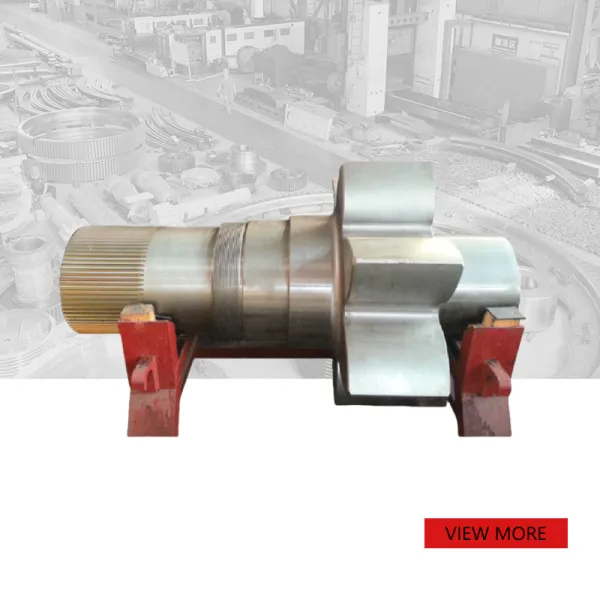

Mining Custom forging steel Large Spline Shaft

PRODUCT PARAMETERS

Description

Application Overview: Critical Components for Mining Machinery

Mining spline shaft are essential transmission components in heavy-duty equipment such as hoists, tunnel boring machines, crushers, and conveyor systems. These applications demand exceptional durability to endure extreme conditions.

1. Raw Material Selection: Foundation of Durability

Mining spline shafts demand materials that combine strength, toughness, and resistance to extreme conditions. High-performance alloy steels like 42CrMo or 20CrMnTi are preferred for their exceptional hardenability, wear resistance, and ability to endure high loads, vibrations, and abrasive environments. All raw materials undergo rigorous testing, including chemical composition analysis and mechanical property verification, to meet international standards, ensuring reliability from the very first step.

2. Forging & Blank Forming: Precision in Structure

Forging is critical to eliminating internal defects and optimizing the metal’s grain structure. By precisely controlling forging temperatures and deformation rates, issues like porosity and shrinkage cavities are minimized, enhancing the shaft’s structural integrity. Post-forging treatments such as normalizing or annealing refine the microstructure, improving machinability and preparing the material for subsequent heat treatment stages. This step ensures the blank meets the dimensional and mechanical demands of mining equipment components.

3. Heat Treatment & Machining: Balancing Strength and Precision

Heat treatment defines the final performance of the spline shaft. The process begins with quenching and tempering, balancing strength and toughness for demanding mining applications. Key areas like spline teeth undergo localized surface hardening (e.g., induction hardening or carburizing), achieving a surface hardness of HRC 50–60 to resist wear and fatigue.

For dimensional accuracy, advanced machinery such as CNC lathes, dedicated spline milling machines, and turn-mill centers are employed. Final grinding of critical surfaces ensures tight tolerances, meeting the high-precision requirements of mining drivetrains.

4. Quality Inspection & Performance Validation: Client-Driven Options

We offer:

- Customized inspection reports detailing material composition and hardness testing (available on request).

- Third-party testing coordination to verify compliance with international standards or project-specific requirements if requested by the client.

Key Advantages of Our Mining Spline Shafts

- Superior Material & Structural Integrity

Crafted from high-strength alloy steels (e.g., 42CrMo/20CrMnTi), our shafts deliver unmatched durability under extreme mining conditions. Advanced forging and heat treatment processes eliminate internal defects, ensuring a dense, uniform microstructure that resists fatigue and deformation.

- Precision Engineering for Reliability

Utilizing CNC machining, dedicated spline milling, and precision grinding, we achieve ultra-tight tolerances and smooth surface finishes. This guarantees seamless integration into complex drivetrains, minimizing vibration and misalignment risks in high-torque applications.

- Enhanced Surface Hardness & Wear Resistance

Localized induction hardening or carburizing boosts spline tooth surface hardness to HRC 50–60, significantly extending service life in abrasive, high-impact environments.

- Flexible Quality Assurance

Standard Inspections: Dimensional checks, hardness testing, and material analysis included by default.

Optional Third-Party Verification: Support for certification upon client request, ensuring compliance with international standards.

- Tailored Solutions for Diverse Mining Equipment

Engineered to meet the demands of hoists, crushers, conveyors, and tunneling machines, our shafts excel in:

High-load torque transmission

Corrosive/dusty environments

Shock-vibration resistance

Feel free to contact us for more information or assistance.