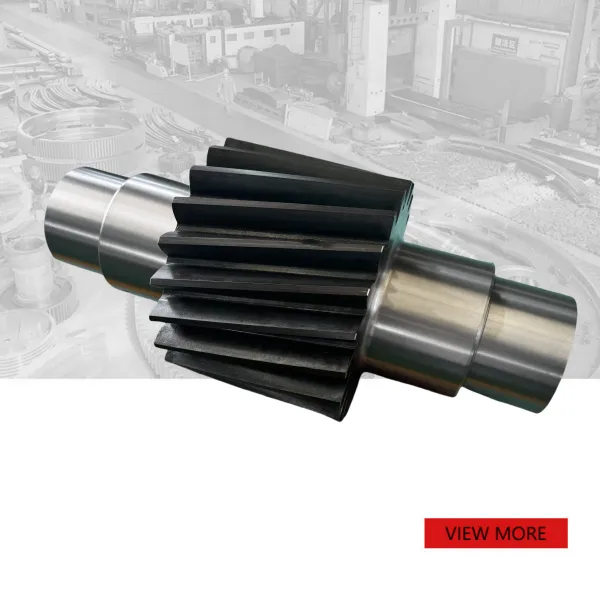

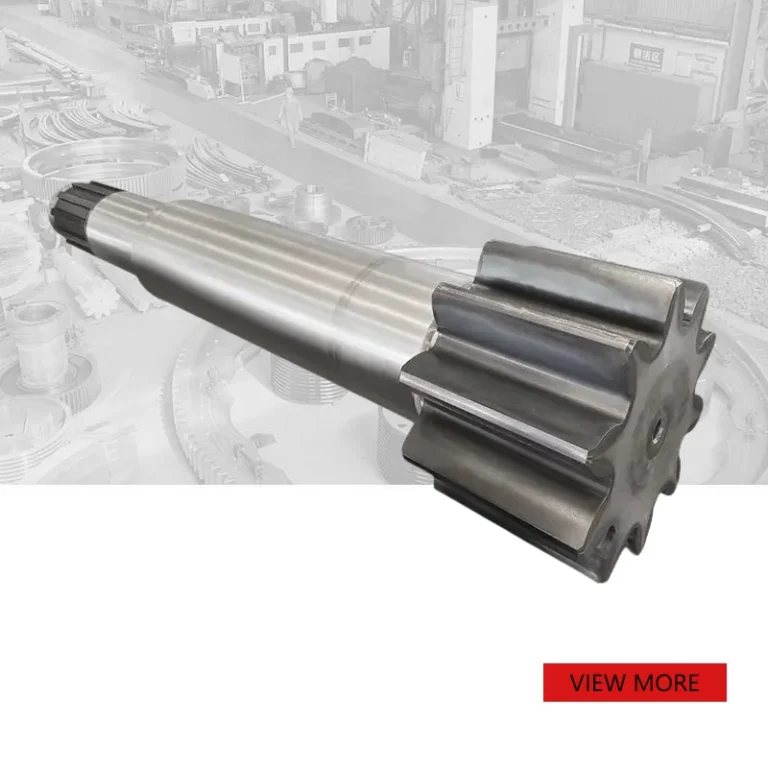

Industrial Transmission Custom Forging 42CrMo Herringbone Gear Shaft

PRODUCT PARAMETERS

Description

herringbone gear shaft

Herringbone gear shaft Overview

As a key load-bearing component in the field of mechanical transmission, the herringbone gear shaft can fully offset the axial force generated during transmission by virtue of its symmetrical tooth profile structure. This solves the pain points of ordinary helical gears, such as high axial load and easy wear. Made from forgings and processed through multiple precision procedures, It maintains stable transmission under heavy-load, high-speed, and continuous operation conditions, thus serving as the “power transmission core” for heavy-duty equipment in mining, metallurgy, shipbuilding, and wind power industries.

Production process of the Herringbone Gear Shaft

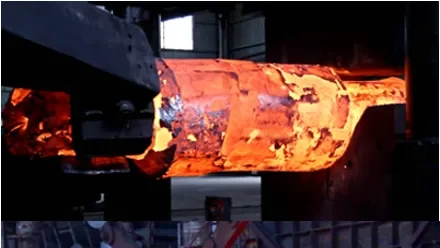

1. forging blank

First, 42CrMo alloy structural steel round billets are selected as raw materials. A spectral analysis is conducted to strictly test the content of elements—with carbon (0.38%-0.45%) and chromium (0.9%-1.2%) meeting standards—to ensure material qualification. Subsequently, the round billets are heated to the forging temperature range of 1100-1200°C. Free forging or die forging is adopted for pressing, which refines the metal grains and densifies the structure. Meanwhile, a rough blank shape matching the herringbone gear shaft profile is pre-forged, with a 10-15mm allowance reserved for subsequent processing. This enhances the shaft’s impact and fatigue resistance, preventing structural fractures during later use. After forging, the rough blank undergoes slow cooling to eliminate forging stress and avoid cracking, ultimately producing a forging base material for the herringbone gear shaft that meets dimensional requirements.Then, ultrasonic testing is performed to check for internal defects such as looseness and inclusions in the forging, ensuring no hidden damage in the base material.

2.Rough Machining

This stage focuses on shaping the basic contour of the herringbone gear shaft body. A CNC lathe is used to perform cylindrical turning, end face leveling, and shaft shoulder machining on the pretreated forging. This precisely controls the basic dimensions of the diameter and length of each section of the shaft body—for example, the initial forming of key parts such as the journal and step surface. Considering potential deformation during subsequent heat treatment, a 3-5mm machining allowance is reserved in areas such as the tooth profile processing zone and precision mating surface at this stage. This prevents the final dimensional deviation from exceeding the standard range while reducing the cutting amount during finish machining to improve processing efficiency.

3.Heat Treatment

Targeted heat treatment is applied to balance the overall toughness of the herringbone gear shaft and the wear resistance of its tooth surface. First, overall quenching and tempering are conducted: the gear shaft is heated to 860-880°C, held for 2-3 hours, and then oil-cooled to room temperature. This brings the core hardness of the shaft body to HB 220-250, ensuring the herringbone gear shaft is not easily bent or broken when bearing heavy loads and impacts. Subsequently, high-frequency induction hardening is performed on the tooth surface: an induction heating method is used to locally heat the tooth surface to 900-920°C, followed by rapid water spray cooling. This increases the tooth surface hardness to HRC 58-62, significantly enhancing the wear resistance of the teeth and extending the service life of the herringbone gear shaft (up to 8,000 hours or more under normal working conditions). After heat treatment, low-temperature tempering is carried out to further eliminate internal stress and stabilize the workpiece dimensions.

4.Precision Machining

This stage focuses on detail optimization to ensure the herringbone gear shaft can be accurately assembled and operate stably.A cylindrical grinder is used for precision grinding of key parts such as the journal and bearing mating surface,This ensures seamless adaptation with equipment bearings and couplings, avoiding vibration caused by excessive assembly clearance. A combination of “manual filing + grinding wheel polishing” is adopted to completely remove burrs from parts such as the tooth root and keyway edges, preventing damage to seals or accessories during assembly.Finally, the symmetry of the keyway is tested and calibrated,guaranteeing stability during power transmission and preventing issues such as slippage and torque loss.

5.Testing

Testing is conducted to ensure each herringbone gear shaft meets quality standards. appearance and dimensional inspection is performed,non-destructive testing is carried out,precision testing, performance testing,Only products that pass all tests will be accompanied by a material report, heat treatment record, and quality inspection certificate before being stored in the warehouse for delivery.Of course, we also support third-party testing.

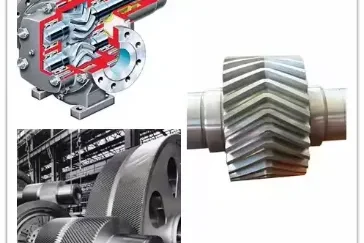

Application Scenarios of the Herringbone Gear Shaft

| Application Field | Compatible Equipment | Core Functions |

|---|---|---|

| Mining Machinery | Large crushers, hoists, scraper conveyors | Transmits high torque (up to 5000 N·m), withstands impact loads during ore crushing, and ensures uninterrupted continuous operation |

| Metallurgical Equipment | Rolling mills, continuous casters, steelmaking converters | Precisely controls equipment speed (error ≤ 0.5%), counteracts axial forces during rolling, and ensures steel processing accuracy (thickness tolerance ±0.1 mm) |

| Marine & Wind Power | Ship propulsion systems, wind turbine gearboxes | Resists high humidity and salty environments (phosphated surface for corrosion resistance), transmits high-power(over 2 MW in wind power applications) |

| General Heavy Industry | Large reducers, presses, injection molding machines | Reduces energy loss in transmission (5%-8% more energy-efficient than standard shafts), enhances equipment operational stability, and reduces maintenance frequency |

Advantages

- Superior Base Material Performance: Made from forgings, the herringbone gear shaft has a denser metal structure compared to those processed from ordinary round steel. Its impact and fatigue resistance are increased by more than 40%, making it suitable for high-load working conditions of heavy-duty equipment.

- Self-Balancing Axial Force: The left-right symmetrical tooth profile of the herringbone gear shaft can fully offset the axial force generated during transmission. There is no need to install additional thrust bearings, which simplifies the equipment structure and reduces assembly and maintenance costs.

- High and Stable Transmission Efficiency: The tooth surface undergoes precision grinding, resulting in a meshing area that is more than 30% larger than that of ordinary helical gears. The transmission efficiency can reach 98.5%, while vibration and noise are reduced (operating noise ≤75dB), making it suitable for 24-hour continuous operation scenarios.

- Strong Customization Adaptability: According to customer equipment requirements, the herringbone gear shaft can be customized in terms of module (2-10mm), number of teeth (15-80 teeth), shaft diameter (30-200mm), keyway specifications, and surface treatment methods (galvanizing, blackening, phosphating) to meet the adaptation needs of different types of heavy-duty transmission systems.

About Us

More than 80% reason of mechanical parts’ working life depends on hot processing (steel making, forging/casting , welding, heat treatment). Our eight metal material experts form a team to control our raw material’s internal quality and mechanical properties from the source,in this way to improve our products’ service life.

We have a professional senior engineer team with more than years experience on material,hot and cold processing.

Contact us