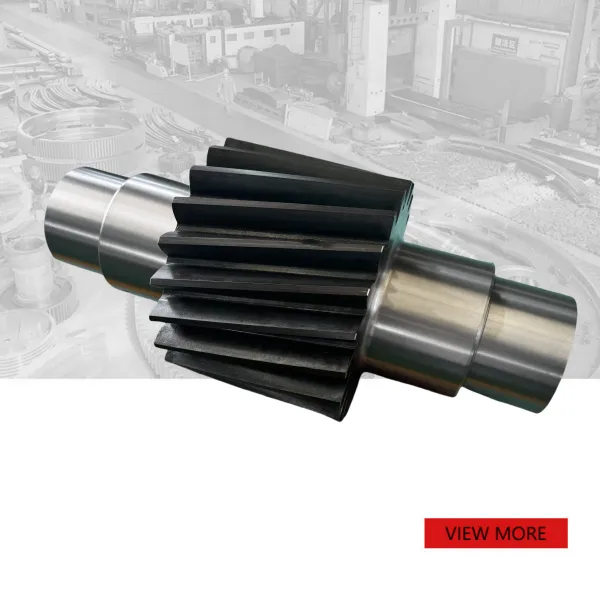

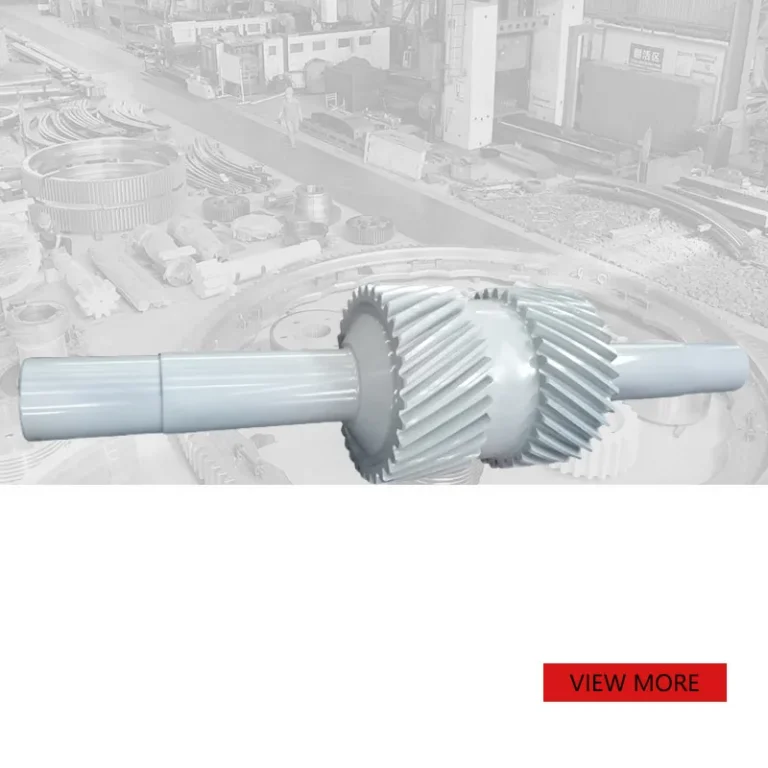

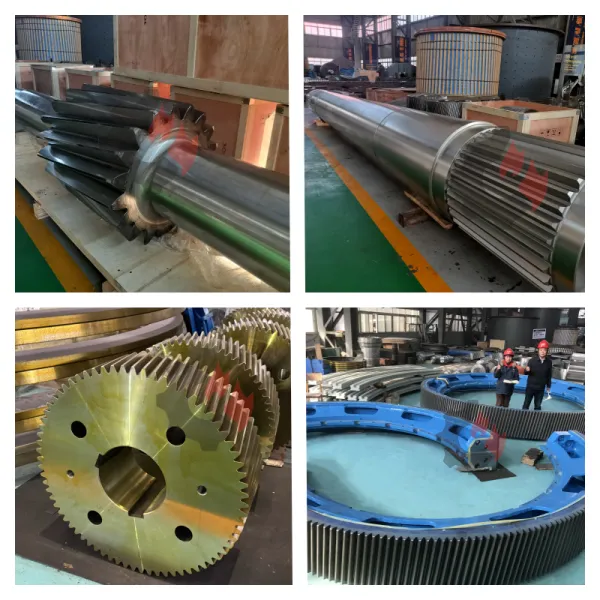

High-strength 42CrMo alloy steel hardened surface helical gear shaft

PRODUCT PARAMETERS

Description

This large module helical gear shaft is a high-performance drivetrain component designed for extreme operating conditions. Crafted from premium 42CrMo alloy steel, it features a robust helical tooth profile, heat treatment, and precision finish machining—making it ideal for applications requiring high torque transmission, durability, and long service life.This gear shaft is built to endure the rigors of mining, metallurgy, marine propulsion, and heavy industrial equipment.

| Feature | Description |

|---|---|

| Material | 42CrMo Alloy Steel – High strength, excellent fatigue resistance, superior hardenability |

| Heat Treatment | Quenching + Tempering (core: 30–40 HRC) + Surface Hardening (58–62 HRC) via carburizing/nitriding |

| Tooth Profile | Helical design reduces noise, vibration, and axial load; improves load distribution |

| Surface Finish | Precision grinding ensures accurate pitch, backlash control, and smooth meshing |

| Dimensional Accuracy | IT6–IT7 tolerance class; suitable for high-speed, high-precision applications |

| Load Capacity | Designed for heavy-duty use: Torque up to 200 kN·m, radial loads >80 kN |

Applications

This gear shaft is widely used in:Mining Equipment: Crusher drives, conveyor systems, underground excavators

Metallurgical Industry: Rolling mill gearboxes, continuous casting machines

Marine Propulsion: Ship reduction gears, thruster units

Heavy Machinery: Cement mills, wind turbine gearboxes (specialized versions)

Its ability to handle frequent starts/stops and shock loads makes it indispensable in harsh environments.

Manufacturing Process Flow

Hot Forging

Shaped into near-net blank using cross wedge rolling or die forging to refine grain structure.

Heat Treatment

Quenching & tempering for core toughness

Carburizing or nitriding for surface hardness (58–62 HRC)

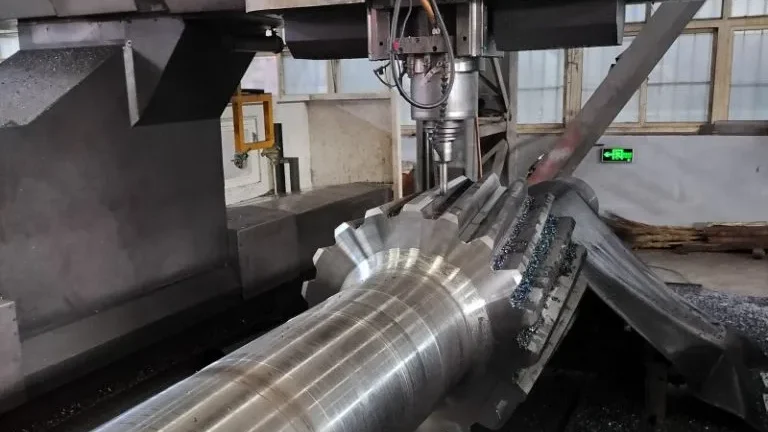

Precision Machining

CNC hobbing → gear grinding → shaft finishing → final inspection

Quality Control

Hardness testing at three points: tooth surface, root, and shoulder

CMM measurement, NDT (ultrasonic/magnetic particle)

Tooth profile and runout analysis

Packaging

Protected with anti-rust oil and bracket packaging for safe transport.

Why This Gear Shaft Stands Out

🔹 “Steel Armor” Design: Hard surface resists wear; tough core absorbs impact

🔹 Longer Service Life: Up to 50% longer than standard carbon steel shafts

🔹 Reduced Maintenance: Precise meshing minimizes noise and vibration

🔹 Customizable: Available in various modules, diameters, lengths, and hardening depths

Perfect for OEMs & Industrial Upgrade Projects

Whether replacing worn-out components or designing new heavy machinery, this large module helical gear shaft delivers:

- Reliable performance under continuous high load

- Seamless integration into existing gearboxes

- Proven track record in mining, metallurgy, and marine sectors

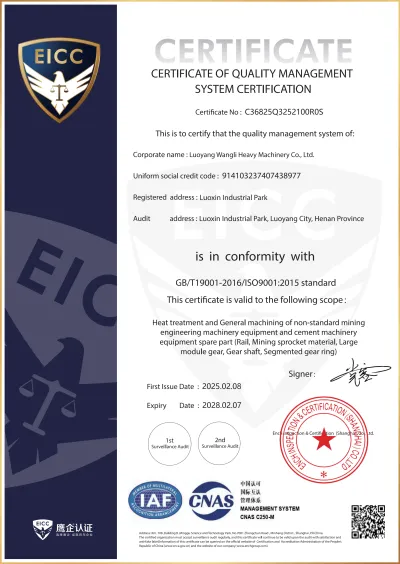

Why Choose Our Gear Shafts?

✅ High Reliability: Proven performance in harsh industrial environments

✅ Customization Available: Module, tooth count, bore size, keyway, spline, length

✅ Full Process Control: In-house forging, heat treatment, machining, and inspection

✅ Traceable Quality: ISO-compliant quality management with full documentation

✅ OEM/ODM Supported: Tailored solutions for global partners

FAQs of shaft

–How long is the delivery time? 45-80 days

–What are the packaging methods?

According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

Recommended for You

Contact us