Hot Selling Product Hight Quality External Gear Slewing Gear

PRODUCT PARAMETERS

Description

slewing bearing (turntable bearing) handles axial, radial, and overturning loads, acting as a machine “joint.” Made from high-strength alloy (HRC55–62 hardness), it offers low friction, long life, and easy maintenance. Widely used in excavators, cranes, wind turbines, and CT scanners. Essential for rotational motion in heavy machinery.

CNC vertical lathes

as core equipment for slewing bearing production, achieve high-precision vertical machining (IT8 precision class, surface roughness of Ra 1.6 μm) to efficiently complete precision turning of large inner/outer rings and gear rings. They simultaneously process axial, radial, and overturning moment loads, meeting requirements for gear ring quenching, positioning accuracy, and thermal stability in multi-type slewing bearings such as four-point contact ball bearings and crossed roller bearings. This significantly improves manufacturing efficiency and reliability for rotary mechanisms in fields like construction machinery and wind power equipment.

Plane grinding machines

Plane grinding machines serve as critical equipment in slewing bearing manufacturing, precisely finishing the end faces of inner/outer rings to achieve ultra-high flatness (0.005mm/100mm tolerance) and surface finish (Ra0.4μm), ensuring optimal load distribution, minimal vibration during rotation, and precise axial positioning. This process directly enhances the bearing’s ability to withstand axial/radial forces and overturning moments, meeting stringent requirements for wind power yaw systems, heavy-duty excavators, and robotic joints where rotational stability and fatigue resistance are paramount.

4-meter CNC vertical grinding machines

4-meter CNC vertical grinding machines are pivotal in slewing bearing manufacturing, enabling ultra-precision finishing of massive inner/outer ring end faces (tolerance ≤0.005 mm/100 mm, Ra 0.4 μm) for 4-meter-diameter components. This ensures optimal load distribution, minimal rotational vibration, and critical axial alignment, directly enhancing the bearing’s capacity to withstand combined axial/radial forces and overturning moments in heavy-duty applications like wind turbine yaw systems, ship cranes, and mining excavators, thereby guaranteeing superior rotational stability and fatigue resistance for critical industrial machinery.

8-meter CNC turning-grinding integrated machines

8-meter CNC turning-grinding integrated machines revolutionize slewing bearing manufacturing by enabling simultaneous precision turning and grinding of massive 8-meter-diameter inner/outer rings in a single setup. This eliminates multi-step machining, achieving ultra-high end-face flatness (≤0.003 mm/100 mm), surface finish (Ra 0.2 μm), and geometric accuracy (IT5 tolerance) critical for wind turbine yaw systems, offshore crane platforms, and heavy mining equipment. The integrated process ensures optimal load distribution, zero thermal distortion during high-torque rotation, and seamless compatibility with four-point contact ball/crossed roller designs—directly enhancing fatigue resistance, rotational stability, and service life in extreme-duty applications where precision and reliability are non-negotiable.

CNC hobbing machines

CNC hobbing machines are indispensable for slewing bearing production, delivering precision gear cutting of large-diameter ring gears (up to 8m) with IT5 tolerance (0.01mm/100mm) and Ra0.4μm surface finish. This process ensures perfect meshing between the slewing ring and drive gear, critical for wind turbine pitch systems, excavator boom rotations, and ship steering mechanisms. By eliminating backlash and guaranteeing consistent tooth profile accuracy, CNC hobbing directly enhances load distribution, rotational smoothness, and fatigue resistance—enabling the bearing to withstand combined axial/radial forces and overturning moments in extreme-duty applications while maintaining zero thermal distortion during high-torque operation.

Gantry Drilling-Milling Centers

Gantry Drilling-Milling Centers serve as critical equipment in slewing bearing production, enabling high-precision multi-axis drilling, milling, and tapping of massive ring gears (up to 8m diameter) with IT6 tolerance (±0.015mm/100mm) and Ra1.6μm surface finish. This integrated process ensures perfect alignment of mounting holes, gear teeth, and sealing grooves in a single setup, eliminating cumulative errors from multiple fixturing. By guaranteeing zero positional deviation (<0.02mm) and uniform hole spacing for critical components like wind turbine yaw drives, ship steering systems, and heavy excavator booms, it directly enhances load distribution, rotational accuracy, and fatigue resistance under combined axial/radial forces. The rigid frame design minimizes vibration during high-force operations, ensuring seamless compatibility with four-point contact ball and crossed roller bearing structures—ultimately extending service life and reliability in extreme-duty industrial applications where precision and structural integrity are paramount.

Stabilization furnaces

Stabilization furnaces are critical in slewing bearing production, precisely eliminating residual stresses from prior heat treatments (e.g., quenching) through controlled low-temperature heating (150–250°C for 2–4 hours). This process ensures dimensional stability (<0.01 mm distortion), microstructural homogeneity, and enhanced fatigue resistance in gear rings and raceways, directly preventing post-heat-treatment warpage that would compromise IT5-level precision (0.01 mm/100 mm tolerance) and Ra0.4 μm surface finish. By guaranteeing zero distortion in critical components (e.g., wind turbine yaw ring gears, ship steering systems), stabilization furnaces uphold the bearing’s ability to withstand combined axial/radial loads and overturning moments under extreme dynamic conditions—ultimately extending service life and reliability in high-stress applications where precision and structural integrity are non-negotiable.

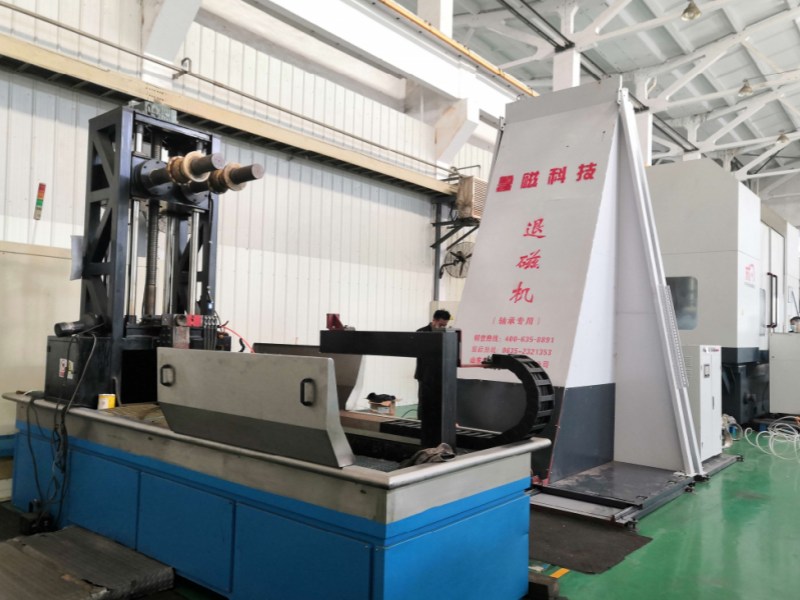

Demagnetization and non-destructive testing (NDT) equipment

Demagnetization and non-destructive testing (NDT) equipment play a critical role in ensuring the quality of slewing bearings. Demagnetizers effectively eliminate residual magnetism in bearing components—such as inner/outer rings and gear rings—after heat treatment or grinding, preventing metal chip adhesion that could cause operational wear or interfere with subsequent assembly. NDT machines, typically using magnetic particle inspection (MPI) or ultrasonic testing (UT), accurately detect surface and subsurface defects such as micro-cracks, inclusions, and porosity, ensuring high-stress areas are free from fatigue risks. Together, these processes guarantee the structural integrity, long-term operational reliability, and compliance with quality standards like ISO 9001 and TS 22163 for slewing bearings used in demanding applications such as wind turbines and construction machinery, making them indispensable final inspection steps in achieving “zero-defect” delivery.

Noise testing

Noise testing in slewing bearing production is primarily used to evaluate noise levels and vibration characteristics during operation. By conducting acoustic measurements under simulated working conditions—such as specific rotational speeds, loads, and lubrication states—it identifies abnormal noises caused by manufacturing errors, improper assembly, or surface defects. This test ensures the product meets stringent acoustic performance requirements (typically ≤65 dB) for applications demanding ultra-quiet operation, such as wind turbines, medical equipment, and precision rotary tables. Consequently, it validates the bearing’s machining accuracy, uniformity of rolling elements, and overall rotational smoothness, serving as a critical quality control step to guarantee “quiet and reliable” performance of high-end slewing bearings in service.

Bearing inner/outer raceway profile meters

Bearing inner/outer raceway profile meters are critical for slewing bearing production, enabling ultra-precision measurement of rolling contact surfaces (inner/outer raceways) via non-contact optical scanning or contact probe technology. They precisely quantify raceway curvature radius, symmetry, surface waviness, and micro-topography (accuracy ±0.5 μm), ensuring optimal line/point contact between raceways and rolling elements (balls/rollers). This validation confirms manufacturing compliance with design specifications for four-point contact ball or crossed roller slewing bearings, directly preventing stress concentration, premature fatigue spalling, and rotational instability caused by raceway deviations. By guaranteeing geometric integrity under extreme loads, these instruments are indispensable for achieving high load capacity, extended service life, and operational reliability in wind power systems, construction machinery, and other heavy-duty applications requiring precision rotational motion.

packaging

In order to avoid the finish products rusted and damaged during the transportation ,we will design the right packing according to the shape,size and usage of the products.

About Us

More than 80% reason of mechanical parts’ working life depends on hot processing (steel making, forging/casting , welding, heat treatment). Our eight metal material experts form a team to control our raw material’s internal quality and mechanical properties from the source,in this way to improve our products’ service life.

Feel free to contact us for more information or assistance.