Gear

Mining machinery bronze & alloy steel Worm & Worm gear

Forging 17CrNiMo6 wear resistant surface carburizing gear

35CrMo Forging Mining large dimeter 12 Segment Arc Tooth

Non-standard customized large diameter 4 large segmented ring gear

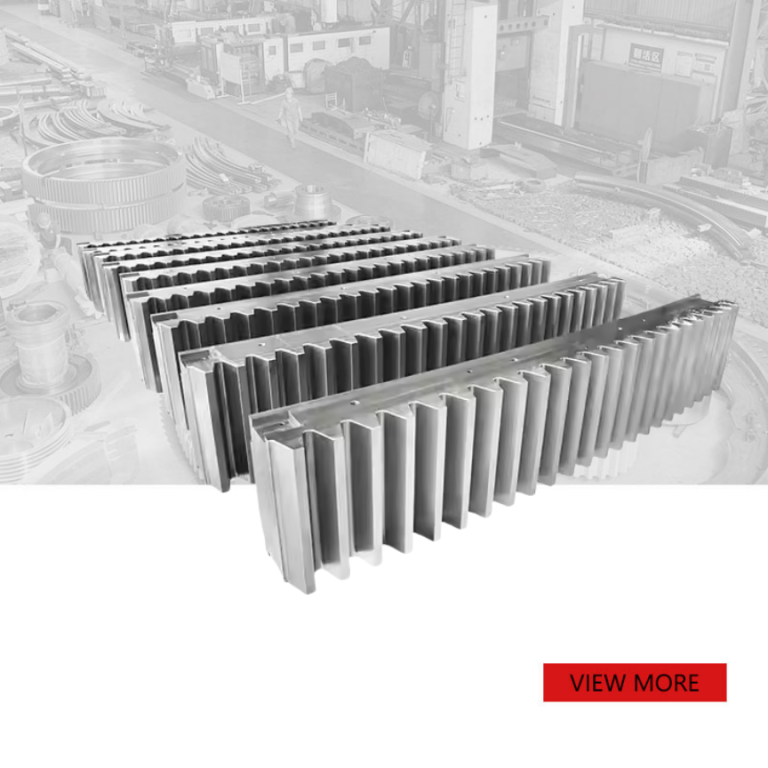

Customized forging high quality segment ring gear

Customized main transmission forged steel large diameter spur gear

Custom forging double helical gear

Non-standard alloy steel large diameter casting Casting gear

Non-standard alloy steel large diameter casting Herringbone gear

Customized 35CrMo forged steel segmented large diameter ring gear

Customized 35# casting Two segment spur girth gear copper mine mill

Casting ZG30# large diameter spur gear conveyor

Overview of Gear

A gear is a mechanical element, usually in the shape of a wheel, with teeth on its edge or surface, which transmits rotational motion and power by meshing with the teeth of another gear. Gears are widely used in various mechanical equipment to change speed, torque, direction of rotation, etc. The design and manufacture of gears require precise calculations and high-precision processing to ensure smooth operation, low noise and long life.

Features of Gear

The tooth design of a gear is crucial to its performance. Common tooth profiles include involute tooth profiles, cycloid tooth profiles, and circular arc tooth profiles. Involute tooth profiles are widely used in industry because of their simple manufacturing and good interchangeability. Module is a basic parameter in gear design, defined as the ratio of the pitch circle diameter of the gear to the number of teeth, and the unit is usually millimeters. It is one of the important factors that determine the size and load-bearing capacity of a gear. The larger the module, the larger the size of the gear and the stronger the force it can withstand. The number of teeth affects the transmission ratio, contact strength, and noise level. Generally speaking, gears with more teeth can provide smoother transmission, but may require more space. The pressure angle refers to the angle between the direction of the force when the gears are meshing and the direction perpendicular to the tangent of the pitch circle. The standard pressure angle is usually 20 degrees, and other angles such as 14.5 degrees or 25 degrees are also used in some special applications. The transmission ratio determines the changes in speed and torque, and is very important for achieving the desired working effect. The manufacturing accuracy of the gear has a great influence on the transmission efficiency, noise, and life. According to international standards, gears have different accuracy levels, and the higher the accuracy, the more stringent the manufacturing requirements. Materials and heat treatment are important. In order to meet the needs of different working conditions, gears can be made of a variety of materials, such as steel, cast iron, bronze, etc., and are often surface hardened (such as carburizing, quenching, nitriding, etc.) to improve wear resistance and fatigue resistance. Proper lubrication can reduce wear and extend gear life, especially under heavy loads or high speeds. Good sealing measures can prevent dust and impurities from entering and protect the gears from damage. Noise and vibration characteristics are very important considerations in applications with high precision requirements.

Specifications Table of Gear

| Feature | Specification |

|---|---|

| Material | Carbon steel, alloy steel, etc. |

| Diameter | φ200mm-φ16000mm |

| Module | m≥1.5mm,Customizable, |

| Pressure Angle | 14.5°,20°,25°,Customizable |

| Gear Type | Involute, Customizable |

Applications of Gear

Our gears are produced according to customers' drawings and requirements. The gears we produce are widely used in many fields and equipment, mainly in industrial machinery, mining machinery, wind power generation, and construction equipment.

Company profile

Established in 2002, Luoyang Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2015.

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are looking for high quality gear products, please feel free to contact us.(sales@citicwl.com)

FAQs of Gear

What determines the efficiency of a gear?

Efficiency depends on factors like material quality, tooth design, and lubrication.

Can gears be made from different materials?

Yes, gears can be manufactured from a variety of materials including Carbon steel, alloy steel, brass, bronze, each offering unique advantages.

What is the significance of the pressure angle in gears?

It affects the gears' contact pattern and influences the smoothness of operation and stress distribution.

How do I choose the right type of gear for my application?

Consider the application's requirements, such as speed, load, and available space, when selecting a gear type.

Are there maintenance requirements for gears?

Regular inspection and proper lubrication are critical to maintaining gear performance and longevity.