Dragline Excavator Parts

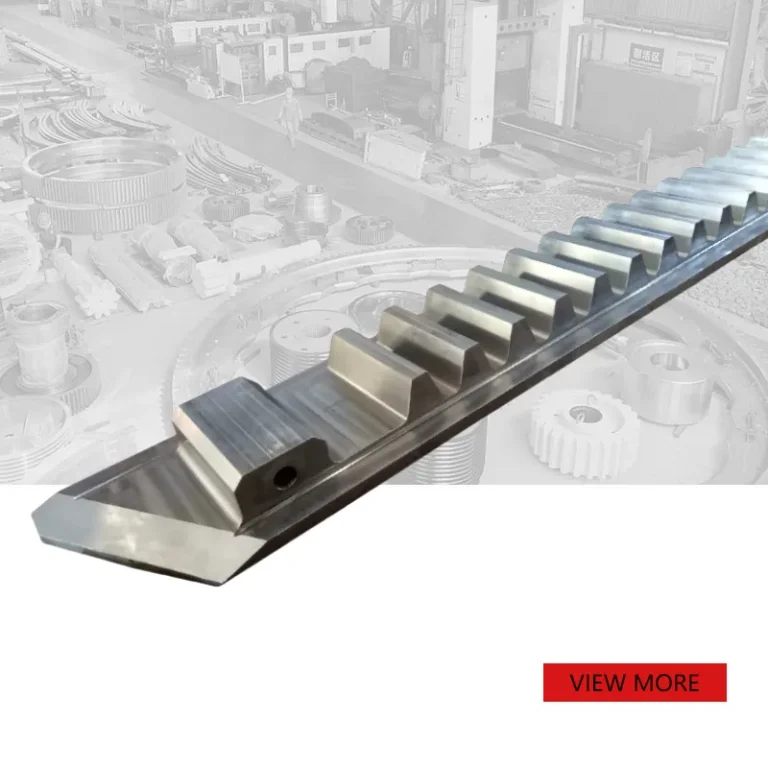

Large mining machinery forging large module helical gear rack

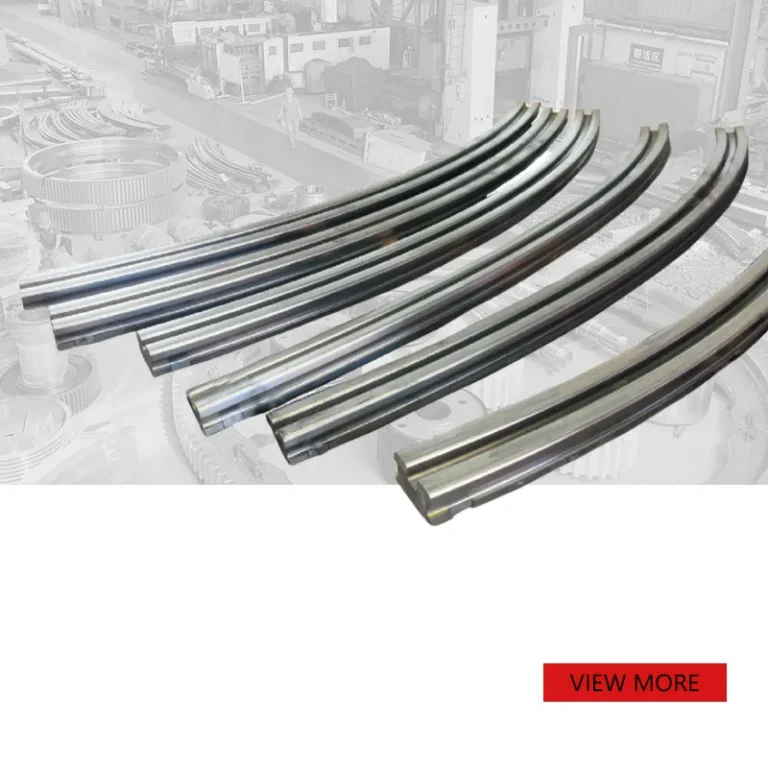

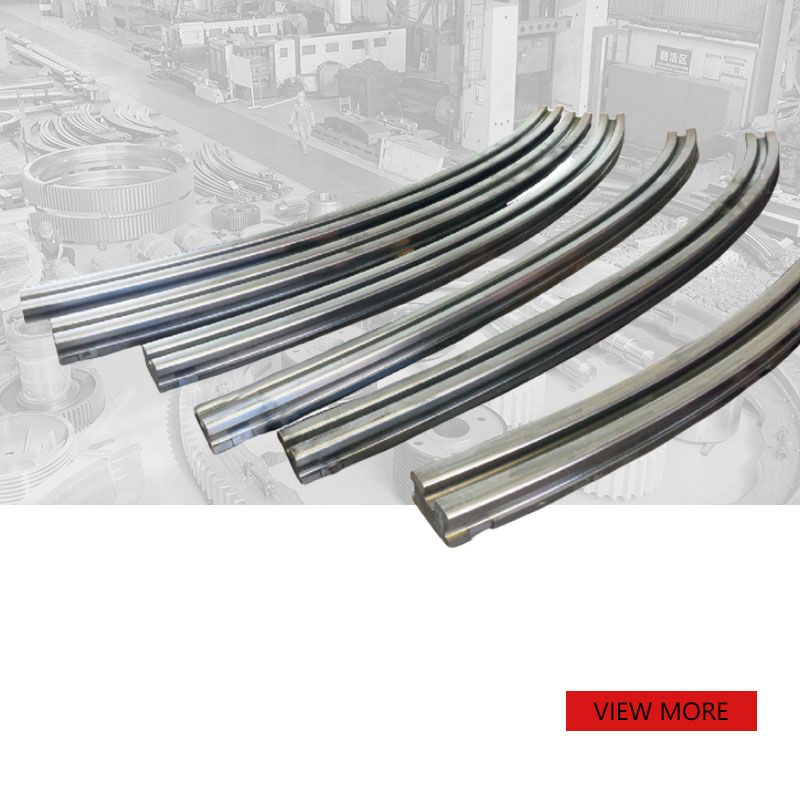

Forging wear-resistant mining machinery spare parts Segment Rail

Customized Large Diameter Non-standard Slewing Bearing for Heavy Excavator

Mining Machinery Dragline Excavator Large Steel Casting Rope Wheel

Mining Large Steel Casting Sheave wheel Custom Rope sheave

Custom forging gear rack for Dragline excavator

Non-standard alloy steel large diameter Shaft coupling

Casting large diameter wear resistant pulley mining dragline

Dragline excavator custom forging rail

Custom forged alloy steel large crane hook

Forging Rope Sheave for Crane

Overview of Dragline Excavator Parts

Dragline excavators are monumental machines used primarily in surface mining operations. The parts that make up these giants are engineered for durability and efficiency, ensuring seamless operation under harsh conditions. From the bucket to the dragline, each component is designed with precision to withstand extreme wear and tear.

Features of Dragline Excavator Parts

Dragline excavator parts boast a range of features tailored for performance and longevity. These include high-strength materials resistant to abrasion, innovative designs for easy maintenance, and components optimized for energy efficiency. Special attention is given to safety features, ensuring operators can work confidently in challenging environments.

Applications of Dragline Excavator Parts

The applications of dragline excavator parts span across various industries, most notably in mining for digging overburden and ore. They're also pivotal in civil engineering projects, such as harbor construction and land reclamation, where precise earthmoving is required. Their adaptability makes them indispensable tools for large-scale excavation tasks.

Company profile

Established in 2002, Luoyang Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2015.

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are looking for high quality Dragline Excavator Parts, please feel free to contact us.(sales@citicwl.com)

5 FAQs of Dragline Excavator Parts

Q: What materials are commonly used in dragline excavator parts?

A: High-strength steel, reinforced aluminum, and braided steel cables.

Q: How often should dragline excavator parts be inspected?

A: Regular inspections vary; buckets may need semi-annual checks, while motors require yearly service.

Q: Can dragline excavator parts be used in marine environments?

A: Yes, with proper material selection and protective coatings, they can withstand marine conditions.

Q: What's the expected lifespan of dragline excavator parts?

A: Lifespans vary from 5 to 20 years depending on the part and operating conditions.

Q: Are dragline excavator parts customizable?

A: Yes, many manufacturers offer customization options to meet specific project requirements.