Customized Heavy Machinery Parts

Wear-Resistant, High-Performance sprocket wheel for Global Mining Operations

Custom Universal Spindle forged 34CrNiMo6 steel mill connecting shaft

Non-standard alloy steel large diameter Casting wheel

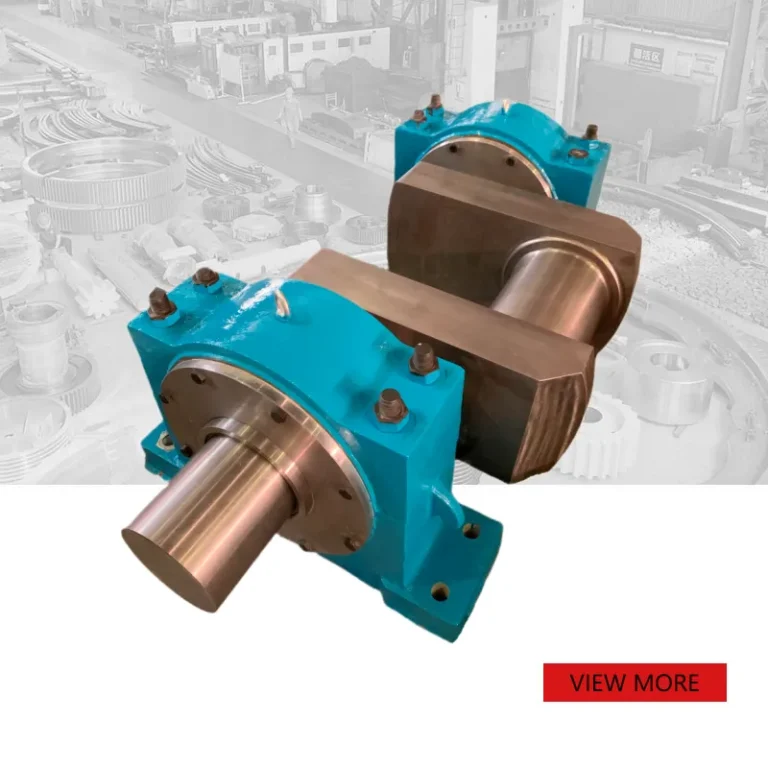

Mining machinery bronze & alloy steel Worm & Worm gear

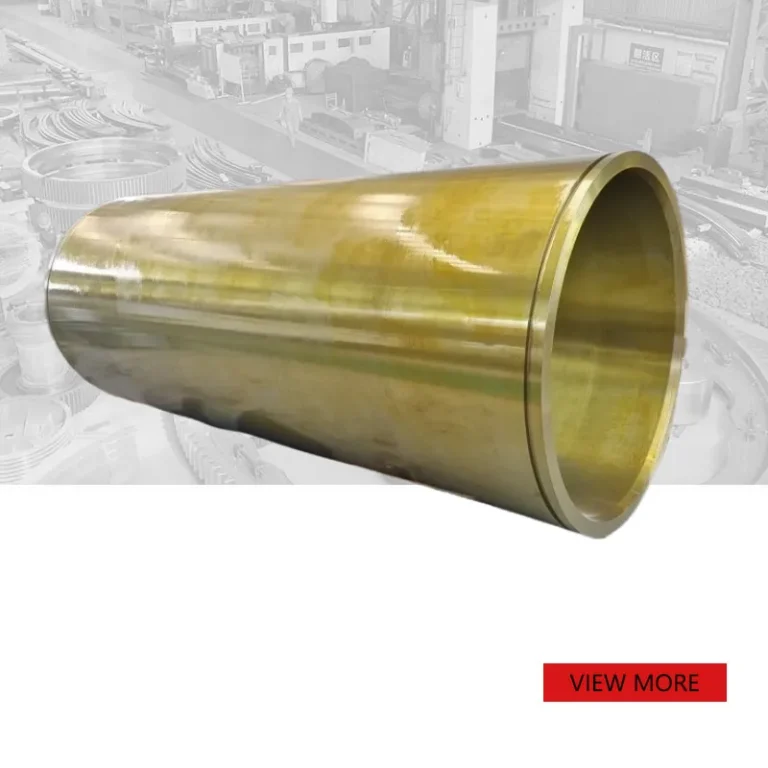

Custom forging large Hydraulic cylinder body

Custom Forging Large Roller Shell High Quality Briquetting Machine Roll Shell Dimpled Roller Shell

Custom eccentric shaft with bearing seat

Mining Machinery parts Casting Jaw Crusher Jaw Plates

Customized High-chromium Alloy Steel Large Cast Crusher Hammer

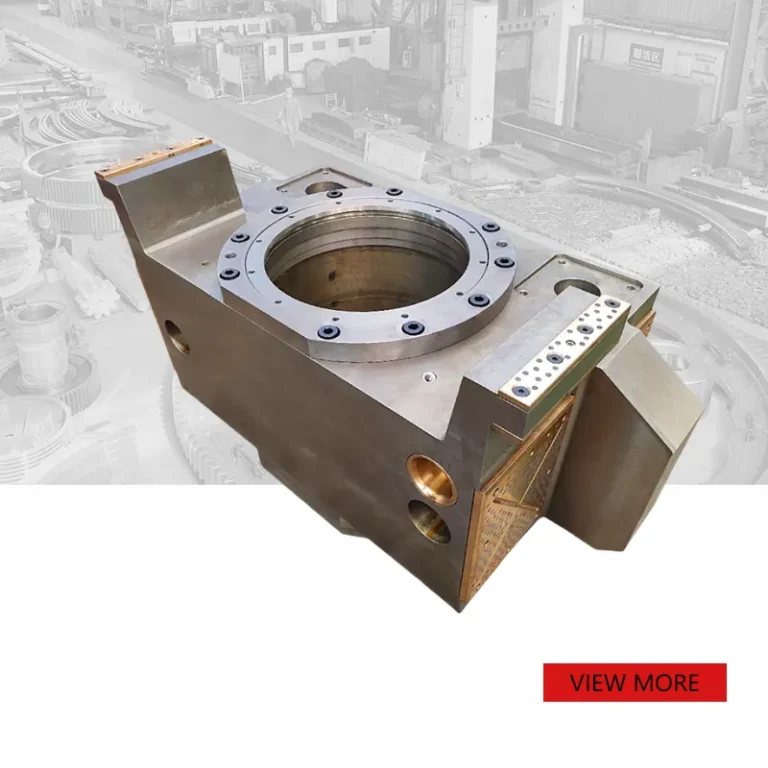

Non-standard alloy steel large diameter casting Bearing seat

Overview of Customized Heavy Machinery Parts

Customized heavy machinery parts are specially designed components tailored to meet the unique needs of various industrial applications. These parts are engineered for durability, precision, and performance, ensuring they fit seamlessly into existing machinery or new innovative designs. They represent a blend of high-quality materials and advanced manufacturing techniques to provide solutions that enhance operational efficiency.

Features of Customized Heavy Machinery Parts

The features of customized heavy machinery parts include bespoke design options that cater specifically to the requirements of the machinery and industry in question. These parts are made from high-strength alloys and composites, offering superior wear resistance and longevity. They also incorporate advanced engineering for easy integration and maintenance, reducing downtime and increasing productivity.

Applications of Customized Heavy Machinery Parts

Customized heavy machinery parts find applications across numerous industries, including mining, construction, agriculture, and manufacturing. Whether it's enhancing the capabilities of existing machines or developing parts for new equipment, these components play a crucial role in improving efficiency, safety, and output. Their adaptability makes them essential for projects requiring specialized machinery solutions.

Company profile

Established in 2002, Luoyang Wangli Heavy Machinery Co.,ltd. focus on metal research and mining machinery spare parts. Our factory located in Luoyang, one of important base for heavy machinery in China. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2015.

Our mainly products: dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are looking for high quality Customized Heavy Machinery Parts, please feel free to contact us.(sales@citicwl.com)

5 FAQs of Customized Heavy Machinery Parts

Q: Can any machinery part be customized?

A: Yes, with modern manufacturing techniques, most parts can be custom-designed to fit specific requirements.

Q: How long does it take to customize a part?

A: The timeline varies based on complexity but typically ranges from a few days to several weeks.

Q: Are customized parts more expensive than standard ones?

A: Generally, yes, due to the design process and material costs, but they offer better value through improved performance and longevity.

Q: What kind of warranty do customized parts come with?

A: Warranties vary by manufacturer but often match those of standard parts, sometimes extending beyond.

Q: Is there a minimum order quantity for customization?

A: Not necessarily; many manufacturers will work on single-part orders depending on the project.