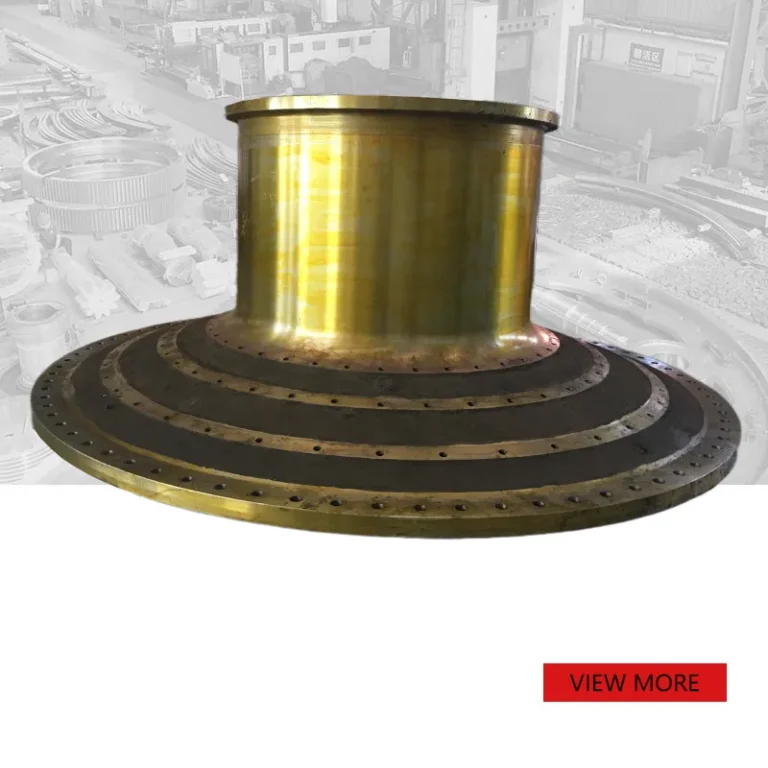

Segmented Bronze Bushing for Kiln Applications

PRODUCT PARAMETERS

Description

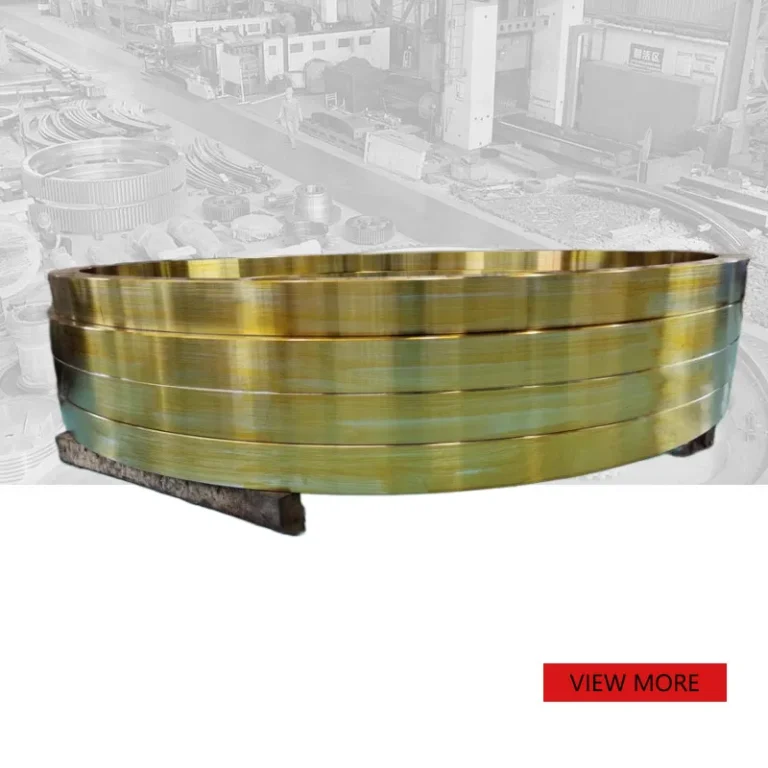

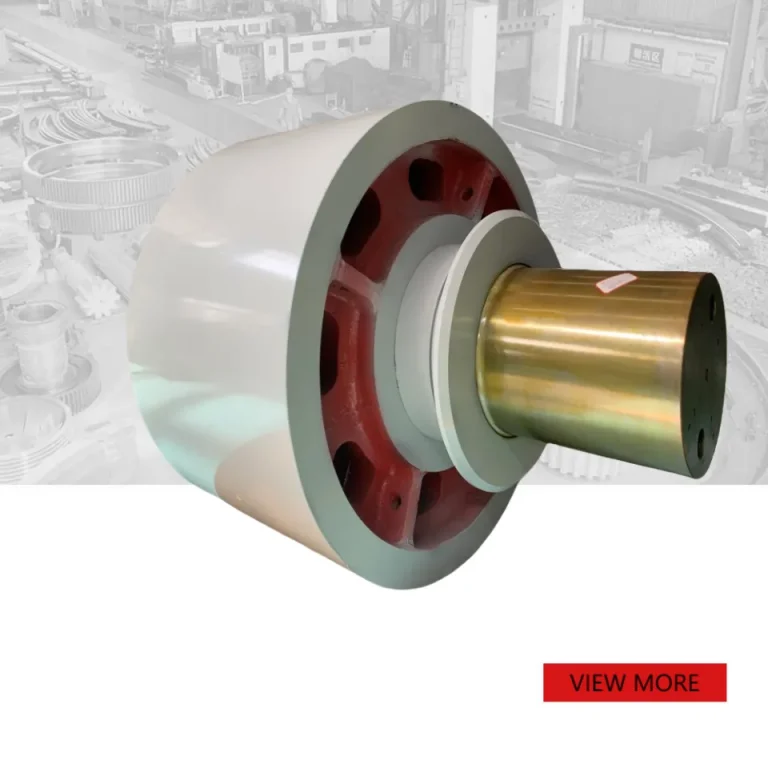

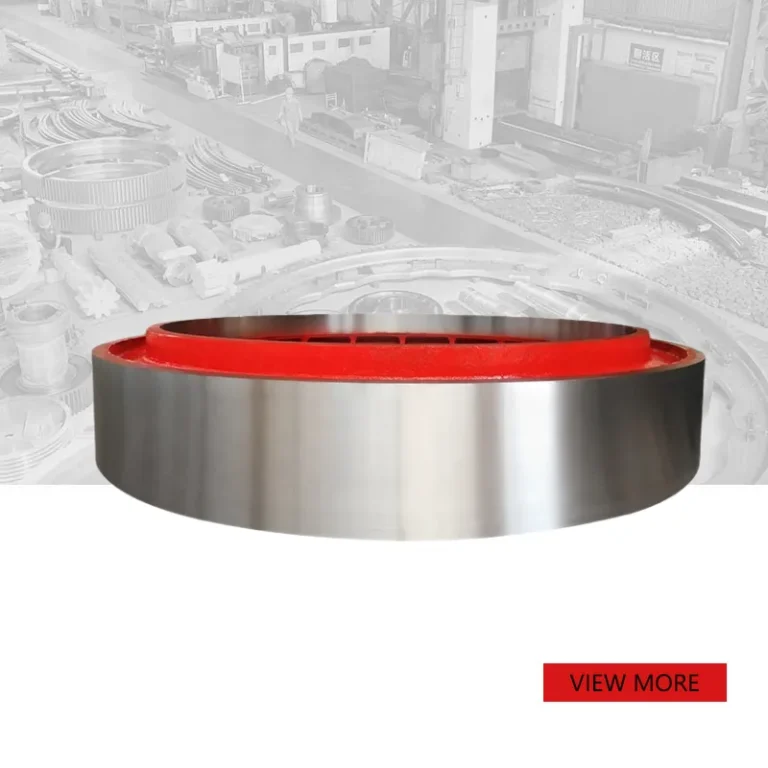

In industries such as cement, metallurgy, and chemicals, the contact surface between the roller bearing and the riding ring in kiln systems is a critical “joint” that withstands immense loads and continuous friction. Traditional monolithic bronze bushings are inconvenient to install, dismantle, and maintain. Localized wear often necessitates full replacement, leading to high costs. Our segmented bronze bushing, crafted from premium high-leaded brass (ZCuAl10Fe3) or tin bronze (ZQSn10-1/ZQAl9-4), offer a precise casting solution. Through scientific segmented design, they seamlessly replace traditional bushings, significantly enhancing equipment maintainability and operational stability.

Segmented Bronze Bushing of Manufacturing Process:

1.Casting:

1.1 Utilize medium-frequency induction electric furnaces for melting, with precise temperature control between 1150°C–1200°C to ensure metal purity and optimal fluidity.

1.2 Employ metal mold casting or centrifugal casting to minimize defects like porosity and shrinkage, achieving a dense, uniform microstructure for enhanced mechanical properties.

2.Heat Treatment:

Stress-relief annealing for ZCuAl10Fe3 alloys (heated to 600°C–650°C, held at temperature, then slowly cooled) to eliminate casting internal stresses and prevent deformation during machining or use.

3:Rough Machining:

3.1 Perform rough turning on heavy-duty CNC lathes for outer diameter, end faces, and inner bore, removing bulk material for preliminary shaping.

3.2 Each bushing segment is machined separately to ensure dimensional consistency.

4.Precision Machining:

4.1 Inner Bore Finish Boring/Turning: Conducted on high-precision CNC lathes or boring mills to strictly control dimensional tolerances, ensuring proper clearance with the roller shaft.

4.2 Outer Diameter Finish Machining: Meets interference or transition fit requirements with the roller hub for reliable load transmission.

4.3 Segment Interface Machining: Precision milling or wire-cutting ensures flat, tightly fitted mating surfaces with an interface gap ≤0.05mm, preventing uneven stress distribution.

4.4 Oil Grooves/Channels: Milling circumferential oil grooves or drilling oil holes on the inner bore surface to ensure uniform lubrication and effective oil film formation.

5.Surface Treatment & Deburring:

5.1Deburr all sharp edges to prevent shaft damage during installation.

5.2Clean surface oil stains and metal debris to ensure cleanliness.

6:Final Inspection & Packaging:

6.1Dimensional Inspection: Verify critical dimensions using precision measuring tools.

6.2Visual Inspection: Check for cracks, sand holes, or scratches.

6.3Anti-Rust Protection: Apply anti-rust oil, wrap in moisture-proof film, and package in reinforced plywood crates for safe long-distance transport.

Core Advantages: Why Choose Segmented Bushings?

1.No Major Overhauls – Time and Labor Savings:

No need to dismantle the roller assembly or schedule extensive downtime. Worn or damaged bushings can be quickly removed and replaced by loosening bolts, reducing unplanned downtime by over 60%.

2.Reduced Labor & Lifting Costs:

Eliminates the need for heavy lifting equipment and complex procedures required for monolithic bushing replacement, significantly lowering maintenance costs.

3.High Load Capacity & Impact Resistance for Stable Operation:

3.1 Segmented structure optimized via finite element analysis ensures even load distribution, effectively dispersing the kiln’s massive radial and axial forces.

3.2 High hardness and toughness resist stresses from material impacts and thermal deformation, ensuring smooth roller operation and reduced vibration.

4.Superior Thermal Conductivity & Self-Lubrication:

4.1 Bronze alloys rapidly dissipate friction-generated heat, preventing localized overheating (“burning”) accidents.

4.2 Lubricated surfaces form a protective layer, enabling safe short-term operation even under suboptimal lubrication conditions.

Feel free to contact us for more information or assistance.