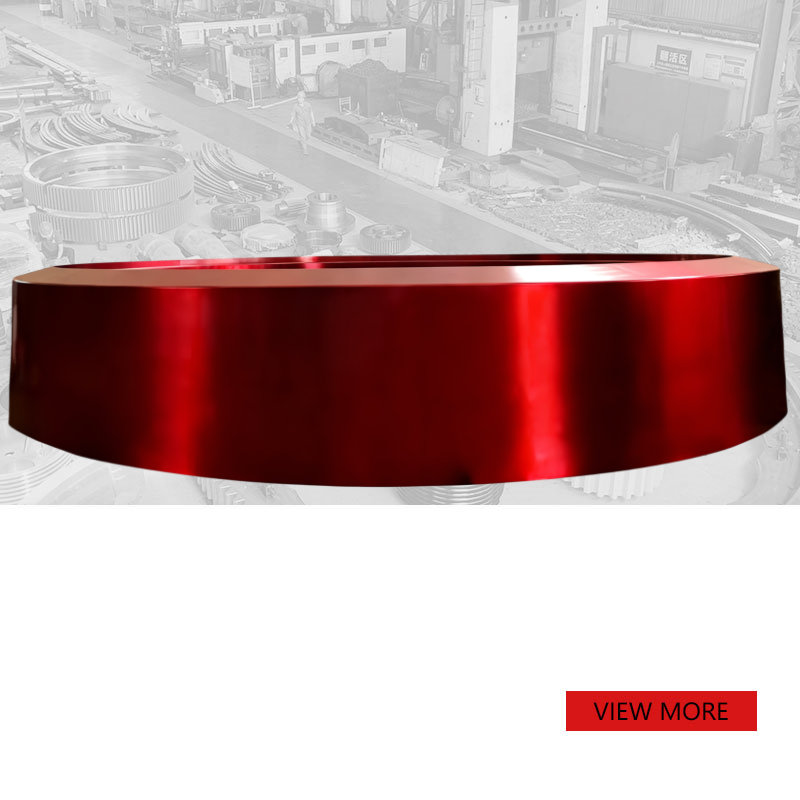

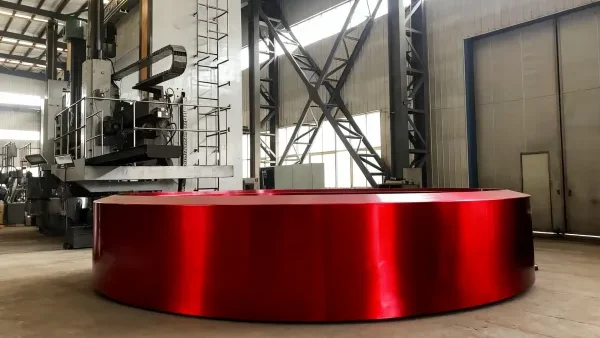

Rotary Kiln Heavy large Rolling Ring forging tyre

PRODUCT PARAMETERS

Description

As a key supporting component of the rotary kiln shell, our rotary kiln tyre directly determines the operational stability of the equipment. It is suitable for heavy-duty kilns in industries such as cement, metallurgy, and chemical engineering, and is a core consumable to ensure continuous production.

The rotary kiln tyre (riding ring) transmits the full weight of the kiln shell—including refractory bricks, internal components, and materials—to the supporting rollers, ensuring smooth and stable rotation. It also enhances the radial stiffness of the shell for improved structural integrity. While cast tyres are typically made from high-quality cast steel such as ZG45 or ZG42CrMo, forged rotary kiln tyres offer superior performance. Through the forging process, forged tyres achieve refined grain structure and denser metal composition, resulting in higher strength, toughness, and wear resistance. This makes forged kiln tyres the preferred choice for ultra-large and heavy-duty rotary kilns in demanding industrial applications.

Production Process

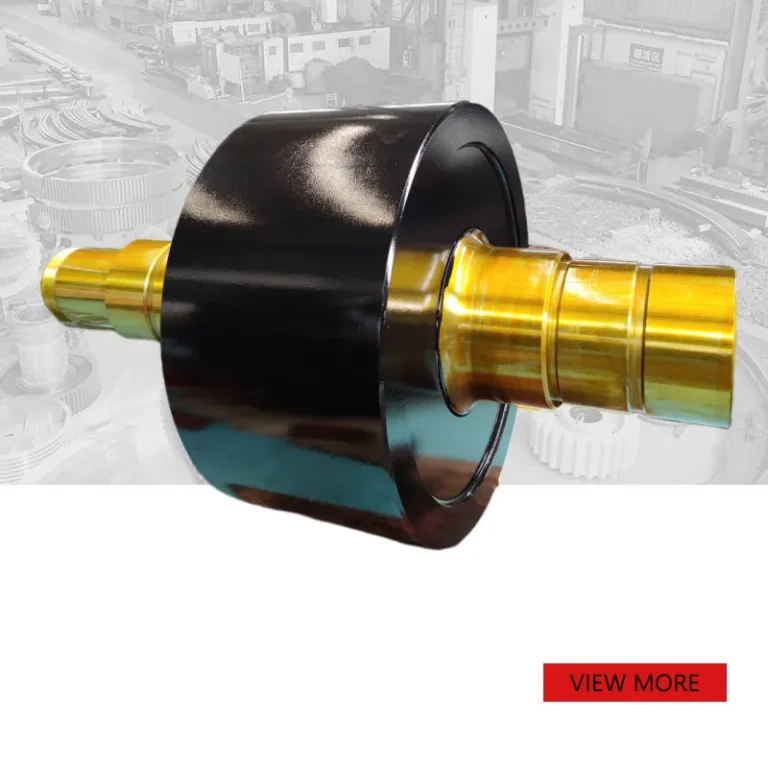

1.Forging

To achieve superior structural integrity and refined grain formation, rotary kiln tyres are forged using advanced electro-hydraulic hammers or quick forging machines—such as 10,000-ton forging equipment—where the process is precisely tailored to the tyre’s dimensions through a sequence of forging steps including upsetting, drawing out, rounding, punching, and hole expanding.

2.Heat Treatment

Following forging, the rotary kiln tyre undergoes heat treatment processes including normalizing and quenching and tempering—where normalizing further refines the microstructure, and quenching combined with high-temperature tempering delivers an optimal balance of high strength and high toughness, ensuring excellent comprehensive mechanical properties with hardness uniformity controlled within HB±15.

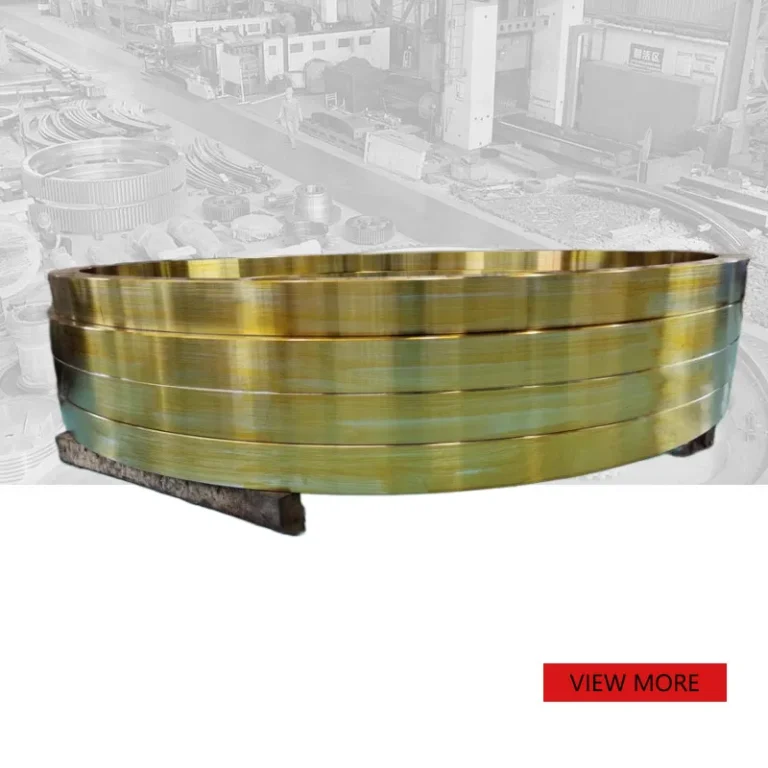

3.Machining

After heat treatment, the rotary kiln tyre undergoes a series of precision machining processes—including rough turning, semi-finish turning, and finish turning—ensuring the outer diameter and end faces achieve a surface finish of Ra1.6, while dimensional accuracy complies with both national standards and customized industry requirements.

4.Inspection

In addition to conventional non-destructive testing (UT/MT), we use imported SPECTRO spectrometers from Germany to conduct chemical composition analysis and mechanical property tests (tensile and impact tests) on the products to verify the quality in all aspects. We also support third-party inspection.

5.Packaging and Delivery

Application Scenarios

- Metallurgy: Large-scale ferronickel rotary kilns, copper smelting rotary kilns (heavy load, high impact working conditions);

- Building Materials: 10,000-ton-per-day cement rotary kilns (scenarios with high stability requirements);

- Environmental Protection: Hazardous waste incineration rotary kilns (with additional requirements for high temperature resistance and corrosion resistance).

Advantages

- Excellent Mechanical Properties: Forged from high-strength alloy structural steels such as 42CrMo and 35CrMo, with a tensile strength of ≥800MPa, yield strength of ≥600MPa, and impact toughness increased by 40%, it can withstand extreme heavy loads and frequent alternating stresses.

- Controllable Dimensional Accuracy: The dimensional tolerance of the forging is controlled within ±0.2mm, and the fit clearance with the shell and supporting rollers is precise, reducing the vibration amplitude by 20% during operation and significantly improving equipment stability.

- Longer Wear-resistant Service Life: The surface hardness after forging reaches HB280-320, the wear resistance is 50% higher than that of cast tyres, and the service life exceeds 10,000 hours, making it suitable for high-impact working conditions in metallurgy, building materials, etc.

Contact us