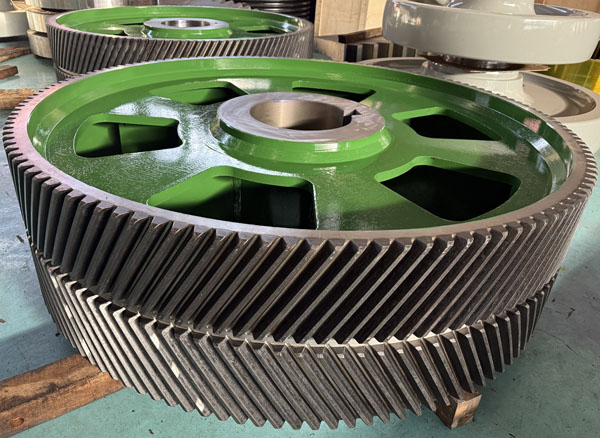

Herringbone gear: Quality starts from its roots, and strength provides the highest level of quality.

Modern industrial equipment makes extensive use of herringbone gears in ships, heavy machinery, wind power generation systems and metallurgy as they offer compact construction with smooth transmission capabilities and strong load-bearing capacities. Herringbone gears are key elements of transmission systems, and their performance has an enormous effect on operating efficiency and longevity of equipment. Their performance is predominantly determined by raw material quality control; Luoyang Wangli Heavy Machinery Co., Ltd firmly upholds this rule with strict controls over material source quality to guarantee every herringbone gear of outstanding quality and performance.

herringbone gear

1. Strict requirements for herringbone gears to be used with materials

Herringbone gears must withstand high-intensity loads with intricate stress distribution patterns during operation, placing great demands on their mechanical composition, cleanliness, and uniformity of material used to manufacture them. Common materials used in herringbone gears include steel, iron and bronze alloys.

(1) Carbon Steel with high-quality and premium-quality specifications.

These materials, such as 45 steel, 40Cr and 42CrMo, feature exceptional strength, toughness, and processing characteristics that make them suitable for medium-speed gear transmissions with lower loads and moderate load capacities.

(2)Alloy Structural SteelWike 20CrMnTi, 20CrNiMo17CrNiMo6, etc, consisting of alloy elements such as molybdenum, chromium, nickel and titanium, are well known for their superior tempering and quenching characteristics, wear resistance and fatigue resistance – these properties make them popularly utilized in high-speed and heavy-duty gear transmissions.

(3) Cast Iron

For instance, gray iron cast iron comes in the form of HT250, while QT500-7 ductile iron features low costs and excellent shock absorption characteristics, making them suitable for light-load and low-speed gear applications.

Steel alloys are widely utilized to manufacture herringbone gears with exceptional performance, but among all, premium grade steel stands out as being most often employed.

2. Herringbone gears must be closely inspected in terms of material control.

For optimal quality and performance, Herringbone Gear has established a material control center staffed by 8 experienced material engineers as well as modern testing equipment from across the world.

By coordinating the operation of this advanced equipment, we’ve managed to conduct an in-depth and multidimensional examination of raw materials used in producing human-shaped gears, making sure each piece of steel used meets quality standards for production.

They meet the highest standards for capacity, transmission efficiency, load-bearing capacity, and wear resistance for service life and customer satisfaction. Customers have a high regard for them.

3. Conclusion

To stay competitive in today’s manufacturing industry, one needs to focus on quality and innovation to stay unbeaten in the marketplace. Our company, with its excellent material control capabilities and talented team, provides not only assurance of herringbone gear quality but also provides greater value and security for its clients.

In the near future, we plan on increasing our investments in material testing and research technologies as we encourage the creation of human-shaped gears with increased performance and reliability, helping high-end equipment manufacturing reach new standards in China. Any needs, please contact: lulu@citicwl.com

Contact us

.jpg)