What Drives Support Roller Strength?Essential Resilience Secrets

In the demanding worlds of mining, power generation, and heavy industry, equipment longevity is paramount. At the heart of countless conveyor systems and massive rotating equipment lies a critical, yet often overlooked, component: the Support Roller. But what truly drives Support Roller strength, transforming it from a simple idler into a pillar of industrial productivity? The answer is a meticulous synergy of engineering precision, advanced materials, and rigorous manufacturing. This deep dive explores the fundamental elements that forge the unwavering resilience of these essential components, ensuring they bear immense loads under the harshest conditions.

1.The Core Pillars of Unyielding Strength

The formidable strength of a Support Roller is not accidental. It is the direct result of intentional design and engineering focused on three interdependent pillars. Understanding these factors explains why a high-quality Support Roller outperforms and outlasts inferior alternatives in critical applications.

1.1.Engineering Design: The Blueprint for Resilience

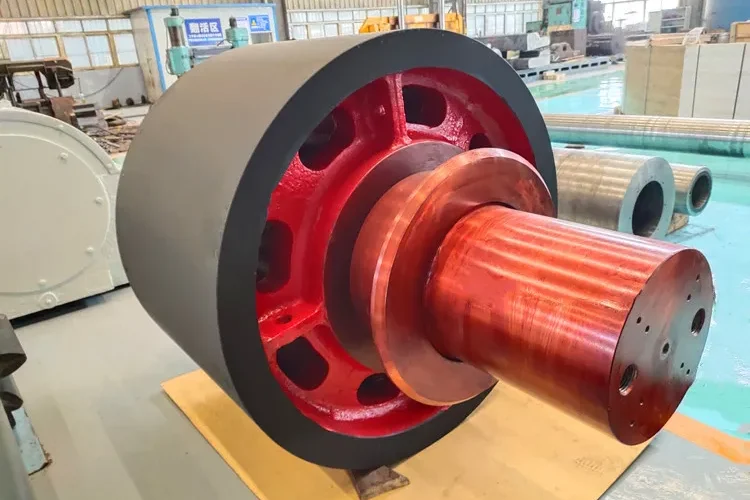

Every high-strength Support Roller begins with intelligent design. Engineers calculate precise load distributions, dynamic stresses, and potential impact forces. The geometry of the shell, the diameter of the tube, and the configuration of the end discs are all optimized to prevent deformation. Furthermore, the strategic placement and type of sealing systems are integral to this blueprint. A robust, multi-labyrinth seal design is crucial, as it protects the Support Roller’s internal bearings from contaminants like dust, slurry, and moisture—the primary enemies of bearing life and, consequently, roller strength.

1.2. Material Science: Choosing the Armor

The choice of material is what transforms a design into a durable reality. For the shell and critical structural parts, high-grade, wear-resistant steel is non-negotiable. Many premium Support Roller manufacturers use precisely welded steel tubes with a significant thickness to resist impact and abrasion. The bearing housings are often crafted from cast iron or forged steel, providing a solid, vibration-dampening foundation for the precision bearings within. This careful material selection ensures the Support Roller can withstand constant wear without compromising its structural integrity.

2.From Raw Material to Reliable Workhorse

Superior design and materials mean little without execution. The manufacturing and quality assurance processes are where the theoretical strength of a Support Roller is physically forged and verified.

2.1.Precision Manufacturing & Assembly

The journey from raw steel tube to a balanced, smooth-rolling Support Roller involves advanced manufacturing. Precise machining of shaft ends ensures perfect bearing fit and alignment. The welding process must be consistent and controlled to avoid weaknesses. A critical, often unseen, step is dynamic balancing. A properly balanced Support Roller eliminates destructive vibration, which is a major source of premature bearing failure and seal damage. This silent operation is a clear indicator of inherent strength and quality.

2.2. The Critical Role of Sealing & Lubrication

Perhaps the most vital internal system is the sealing and lubrication chamber. The strength of a Support Roller collapses if its bearings fail. Advanced sealing technology, often combining grease-purged labyrinths and contact seals, creates an impenetrable barrier. Inside, a reservoir of high-temperature, high-load grease provides continuous lubrication. This sealed environment is the Support Roller’s internal fortress, allowing it to maintain its strength across thousands of hours of operation with minimal maintenance.

3.Where Strength Meets Application: The Support Roller at Work

The ultimate test of a Support Roller’s strength is its performance in the field. Its design purpose is to deliver reliable service in environments that would quickly degrade lesser components.

3.1. Dominating Diverse Industrial Landscapes

The application of Support Rollers is vast. In mining, they carry tons of ore and aggregate on long overland conveyors, facing constant impact and abrasion. In power plants, they support fuel handling systems, often exposed to heat and coal dust. Within the wind energy sector, large-diameter Support Rollers are used in blade alignment and maintenance platforms, where reliability is safety-critical. In each scenario, the core strength drivers—design, material, and sealing—are tailored to meet specific challenges like corrosion, extreme temperatures, or explosive atmospheres.

3.2.The Cost of Weakness: Beyond Immediate Failure

Choosing a Support Roller based on price alone carries hidden costs. A weaker roller may succumb to seal failure, leading to bearing seizure. This not only stops a production line but can cause catastrophic damage to the conveyor belt itself—a far more expensive component. The true strength of a premium Support Roller is measured in total cost of ownership: reduced downtime, lower maintenance labor, and extended belt life. Its resilience is an investment in continuous, profitable operation.

Support Roller Application Overview Table

| Industry/Sector | Primary Equipment | Key Function | Environmental Challenge | Support Roller Strength Focus |

| Mining & Quarrying | Overland & In-Plant Conveyors | Carry bulk materials (ore, coal, aggregate) | High impact, extreme abrasion, dust, moisture | Impact-resistant shell, superior sealing, heavy-duty bearings |

| Power Generation | Coal & Biomass Handling Systems | Transport fuel to boilers | Abrasive dust, heat, sometimes corrosion | Heat-resistant grease, sealed bearings, wear-resistant steel |

| Cement Production | Raw Mill & Clinker Conveyors | Move limestone, clinker, additives | Abrasive dust, high ambient temperature | High-temperature seals, robust construction for abrasive loads |

| Wind Energy | Blade Installation & Service Rigs | Position and support turbine blades during maintenance | Outdoor exposure, high load precision, reliability | Corrosion protection, precision balancing, high load capacity |

| Ports & Terminals | Ship Loaders/Unloaders, Stacker/Reclaimers | Handle bulk commodities for import/export | Corrosive salt air, heavy loads, continuous operation | Corrosion-resistant coatings, ultimate sealing, premium bearings |

4. Strength as a Foundation

So, what drives Support Roller strength? It is the holistic integration of purpose-driven engineering, armored materials, precision craftsmanship, and protective internal systems. It is not a single attribute but a engineered characteristic. For operators in mining, oil, power, and heavy industry, specifying Support Rollers built with these principles is not merely a purchase; it is a strategic decision to build a more resilient, efficient, and productive operation from the ground up. The strength of your support system dictates the strength of your entire material handling process.

Feel free to contact us for more information or assistance.