German Sprocket Client Adopts Luoyang Wangli’s Standards On-Site, Signs Contract Immediately

In October 2025, a German sprocket client visited Luoyang Wangli Heavy Machinery Co., Ltd. for technical discussions. After thoroughly reviewing the company’s independently developed sprocket manufacturing standards, the client immediately decided to abandon the originally planned U.S. standards and signed a supply contract with Wangli on the spot.

Initially, the German client proposed that products adhere to U.S. industry norms. However, after carefully examining Wangli’s comprehensive enterprise standards—from raw material sourcing, heat treatment optimization, to finished product performance verification—the client praised the technical superiority and practical application effectiveness. “Your standards are more scientific, practical, and aligned with our operational needs; we are fully committed to adopting them,” the client noted during the signing ceremony.

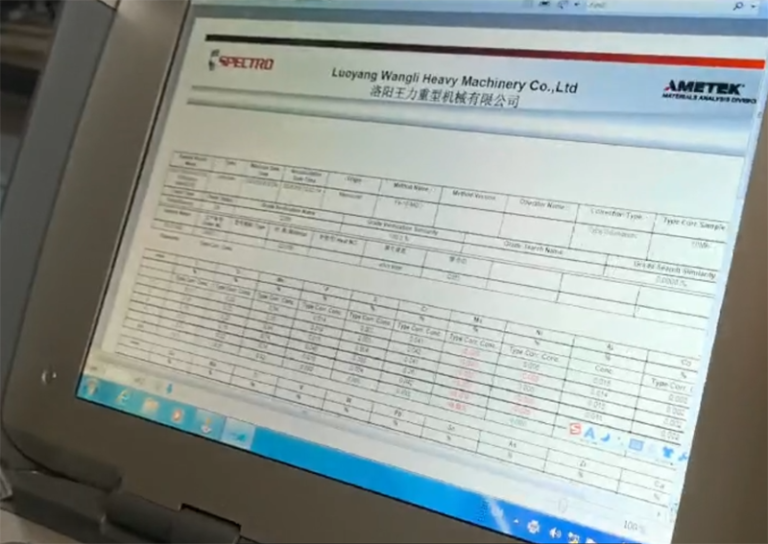

For years, Luoyang Wangli Heavy Machinery has focused on independent innovation in critical sprocket manufacturing. The company has established a full-process self-developed standards system covering raw material purity control, advanced heat treatment, and rigorous performance testing. These standards not only exceed conventional industry norms but also demonstrate significant advantages over mainstream international benchmarks in core metrics such as wear resistance, fatigue resistance, and service life.

“Seeing the client sign the contract right after reviewing our standards is the highest recognition of our work,” said Mr. Wang, the company’s executive. “This isn’t just an order; it’s a testament to global trust in Chinese manufacturing standards.”

This collaboration marks Wangli’s transition from “producing according to standards” to “exporting standards,” providing a vivid example of China’s growing influence in global sprocket manufacturing and industrial component markets.

-edited.webp)