What Is Shaft Transmiss?

In the demanding worlds of mining, oil, power, and wind energy, relentless power transfer is non-negotiable. At the core of this formidable task lies a critical component: the shaft transmiss. But what is shaft transmiss, exactly? Fundamentally, it is an integrated assembly designed for one paramount purpose: to transmit rotational torque and motion from a prime mover, like an engine or turbine, to other vital mechanical parts. This system is the unsung hero, the essential linkage that breathes life into massive machinery, enabling everything from drilling and pumping to generating electricity. Understanding its function is key to appreciating modern industrial infrastructure.

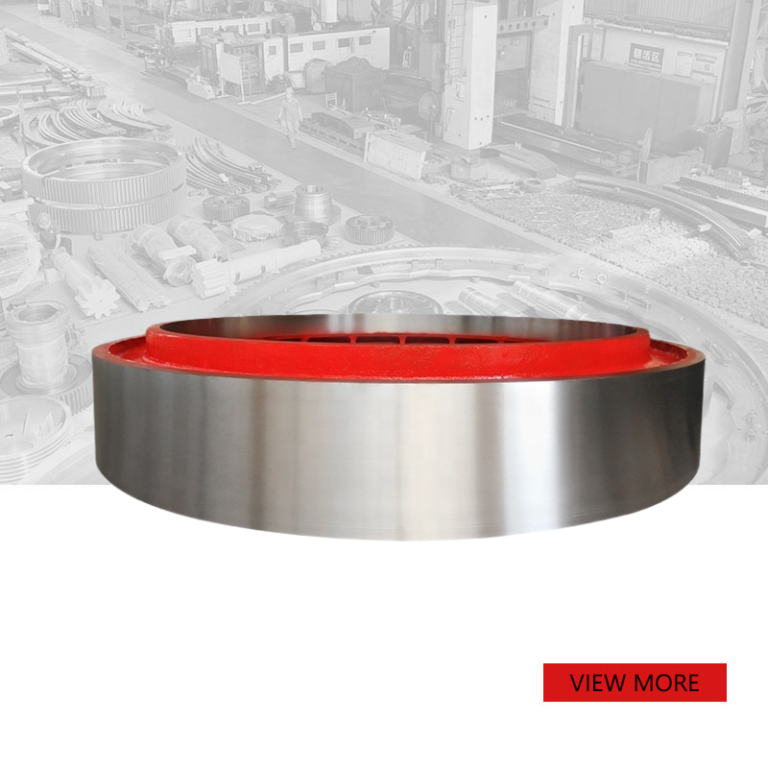

1.An Overview of the Shaft Transmiss System

A shaft transmiss unit is far more than just a simple shaft. It represents a sophisticated synergy of components engineered for precision and endurance. Typically, this includes the central transmission shaft itself, along with crucial elements like couplings, universal joints, bearings, and sometimes gearboxes. Each part plays a pivotal role in ensuring seamless power flow. The design and construction of a shaft transmiss are meticulously calculated to handle specific loads, speeds, and operational stresses, making it a customized solution for extreme industrial environments. Its reliability directly dictates the uptime and productivity of the entire machine it serves.

2.The Defining Features and Superior Advantages

What sets a high-performance shaft transmiss apart from basic drive components? The answer lies in its engineered advantages, built to confront industrial challenges head-on.

2.1.Exceptional Durability & Strength:

Crafted from high-grade alloys and subjected to rigorous heat treatments, a premium shaft transmiss is built to withstand staggering torsional and axial loads. This brute strength is indispensable in mining and oil extraction, where equipment faces constant, shock-level stresses.

2.2.Precision Engineering for Peak Efficiency:

Minimal energy loss is the hallmark of a well-designed shaft transmiss. Precision balancing and alignment reduce vibration and friction, ensuring that maximum power is delivered to the point of use. This operational efficiency translates directly into lower energy costs and improved output for power and wind applications.

2.3.Robust Sealing and Protection

In gritty mining pits or corrosive offshore oil platforms, contamination is a constant threat. Superior shaft transmiss systems incorporate advanced sealing technologies to protect bearings and internal geometries from dust, moisture, and chemicals, drastically extending service life.

2.4.Customization and Adaptability

There is no one-size-fits-all solution. Leading manufacturers offer tailored shaft transmiss designs. This includes specific lengths, diameters, connection interfaces, and material coatings to integrate perfectly with unique machinery across all target industries.

3.Critical Topics and Common Queries Explained

Delving deeper into operational concerns, several vital topics surround the shaft transmiss. A frequent question is: How does a shaft transmiss differ from a simple driveshaft? While both transmit rotation, a shaft transmiss is a far more comprehensive solution. It’s an engineered system that integrates torque transmission with critical ancillary functions like precise alignment accommodation, vibration damping, and environmental protection.

3.1.Maintenance and Longevity

How can you maximize the lifespan of your shaft transmiss? Proactive maintenance is the cornerstone. This involves regular vibration analysis, thermal checks, lubrication management, and seal inspections. Predictive maintenance strategies prevent catastrophic failure, ensuring conti nuous operation.

3.2.The Lubrication Debate

The choice between grease or oil lubrication is pivotal. For moderate-speed applications like mining conveyors, grease offers excellent sealing. However, for high-speed, high-heat scenarios in power generation turbines, oil lubrication is paramount for superior cooling and cleansing. Selecting the correct type is a crucial specification for any shaft transmiss system.

3.3.Addressing Misalignment Challenges

Even minor misalignment can cause premature wear, vibration, and energy waste. Modern shaft transmiss assemblies often incorporate flexible couplings or specialized joint designs to compensate for both angular and parallel misalignment, safeguarding connected equipment.

3.4.The Critical Role of Balancing

For high-speed applications, especially in wind turbines and turbo-machinery, dynamic balancing of the shaft transmiss is non-negotiable. An unbalanced shaft creates destructive harmonic vibrations, leading to bearing failure and structural damage. Precision balancing is therefore a mandatory manufacturing step.

4.Dominant Applications Across Core Industries

The versatility and power of the shaft transmiss make it indispensable. Its application is critical in sectors where failure is not an option.

4.1.Mining & Mineral Processing

Here, shaft transmiss systems drive conveyors, crushers, and giant ball mills. They are built to endure the abrasive, high-impact environment, transferring immense power to process tons of raw material daily. In crushers, the shaft transmiss must manage unpredictable shock loads, requiring advanced metallurgy and fatigue-resistant designs to maximize uptime.

4.2.Oil & Gas Exploration

On drilling rigs and pumping stations, shaft transmiss assemblies are the workhorses. They transmit power from motors to drill heads or pump jacks, operating reliably under extreme pressures and in volatile environments. Specialized coatings on shafts and seals combat corrosion and wear, which is vital for extending service intervals in remote, costly-to-maintain locations.

4.3.Power Generation

In thermal and hydroelectric plants, shaft transmiss units connect turbines to generators. Their ability to handle high torque and maintain precise alignment is crucial for efficient electricity production. The manufacturing of such high-speed shaft transmiss systems involves rigorous dynamic balancing to prevent dangerous vibrations that could compromise the entire plant’s operation.

4.4.Wind Energy

The nacelle of a wind turbine houses a critical shaft transmiss. It connects the low-speed main rotor to the high-speed generator via a gearbox. Modern designs are engineering marvels, often incorporating flexible couplings to handle complex gyroscopic forces. The reliability of the shaft transmiss is paramount here, as maintenance at great heights is a formidable challenge, driving innovation in materials and integrated health monitoring sensors.

| Industry / Application | Primary Role & Equipment | Key Operational Demands & Solutions |

| Mining & Mineral Processing | Drives conveyors, crushers, and ball mills. | Must endure abrasive environments and unpredictable shock loads. Requires advanced metallurgy and fatigue-resistant designs for maximum uptime. |

| Oil & Gas Exploration | Transmits power on drilling rigs and pumping stations (to drill heads, pump jacks). | Operates under extreme pressure and corrosive elements. Utilizes specialized coatings (e.g., tungsten carbide) on shafts and seals to extend service intervals in remote locations. |

| Power Generation (Thermal/Hydro) | Connects turbines to generators. | Demands exact precision and high-speed operation. Involves rigorous dynamic balancing during manufacturing to prevent dangerous vibrations and ensure efficient energy conversion. |

| Wind Energy | Connects the low-speed rotor to the high-speed generator via gearbox in the nacelle. | Must handle complex gyroscopic forces and variable loads. Reliability is paramount due to difficult maintenance access. Drives innovation in flexible couplings, composite materials, and integrated health monitoring sensors. |

In conclusion, the shaft transmiss is not merely a component; it is the fundamental artery of industrial power transmission. Its design, featuring unparalleled strength, precision, and adaptability, answers the rigorous demands of the world’s most critical industries. From powering the crushers in a mine to driving the generators that light our cities, the shaft transmiss remains a testament to engineering excellence, ensuring that the wheels of industry never stop turning.

Feel free to contact us for more information or assistance.