What Is a Trunnion? The Critical Component Powering Large Rotary Equipment In Heavy Industry

In modern heavy industry, large rotary equipment forms the backbone of production—from cone crushers in mining and converters in steelmaking to rotary kilns in cement plants and ball mills in power stations. All rely on one unassuming yet mission-critical component to enable stable, reliable rotation: the trunnion.Often overlooked but never replaceable, the trunnion serves as the structural “spine” that keeps these massive machines running under extreme conditions.

1. What Is a Trunnion? — The Load-Bearing Heart of Rotary Machinery

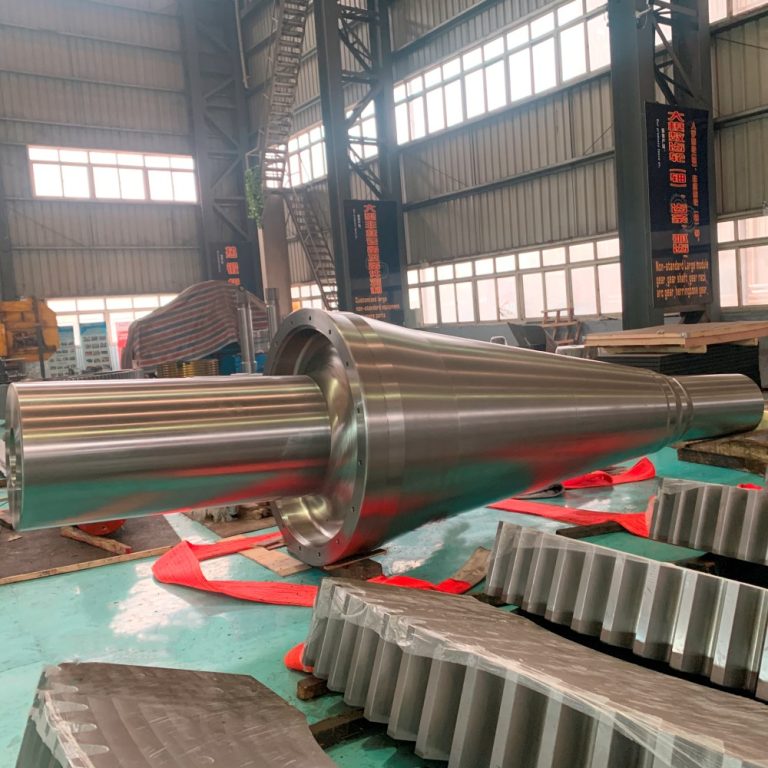

trunnion (also known as a support trunnion or pivot shaft) is a short, robust cylindrical shaft engineered specifically to handle high radial loads while enabling either limited-angle oscillation or continuous low-speed rotation.

In large rotary equipment, trunnions act as the critical interface between the rotating drum or shell and the stationary bearing housings. They support the full weight of the assembly, transmit torque, and ensure smooth, vibration-free operation—even under punishing conditions like dust, heat, shock, and continuous duty cycles.

Unlike standard drive shafts, trunnions prioritize high rigidity, fatigue resistance, wear durability, and long-term maintenance-free performance—making them indispensable in the harshest industrial environments.

2. Key Applications of Trunnions in Major Rotary Equipment

2.1 Cone Crushers (Mining)

2.1.1 Function: Supports the main shaft assembly, enabling the crushing mantle to perform eccentric gyratory motion.

2.1.2 Challenges: High-impact loading, abrasive dust ingress, constant vibration.

2.1.3 Trunnion Requirements: Ultra-high-strength alloy steel (e.g., 42CrMo), dual-seal protection, integrated lubrication channels.

2.2 Rotary Kilns (Cement / Metallurgy / Chemical)

2.2.1 Function: Mounted at both ends of the kiln shell, supported by tire-and-roller assemblies for slow, continuous rotation.

2.2.2 Challenges: Thermal deformation from high temperatures, massive static load.

2.2.3 Trunnion Requirements: Large-diameter forged trunnions, surface induction hardening, precision alignment.

2.3 Converters / Electric Arc Furnaces (Steelmaking)

2.3.1 Function: Serves as the pivot point for tilting mechanisms, allowing molten metal tapping and charging.

2.3.2 Challenges: Intense radiant heat, frequent start-stop cycles, enormous tilting torque.

3.3 Trunnion Requirements: Heat-resistant alloys, high torsional strength, redundant safety design.

2.4 Ball Mills / Semi-Autogenous Mills (Mineral Processing / Power)

2.4.1 Function: Supports the mill shell, enabling slow rotation to cascade grinding media for size reduction.

2.4.2 Challenges: High startup torque, shell imbalance, poor lubrication environment.

2.4.3 Trunnion Requirements: High-toughness materials, anti-fretting coatings, self-aligning bearing interfaces.

3. Four Core Technical Specifications of High-Performance Trunnions

| Specification | Technical Requirement | Industrial Significance |

|---|---|---|

| Material Strength | Alloy steels (e.g., 42CrMo, 34CrNiMo6), quenched & tempered | Resists fatigue failure under heavy cyclic loads |

| Sealing System | Dual-lip seals + labyrinth + positive-pressure lubrication | Blocks dust, moisture, and contaminants |

| Machining Precision | Roundness ≤0.02 mm; coaxiality ≤0.05 mm | Minimizes vibration, extends service life |

| Lubrication Design | Centralized auto-lubrication or self-lubricating bearings | Reduces manual maintenance; ideal for smart mines |

4. Why Trunnion Failure Can Halt Entire Production Lines

When a trunnion fails—due to cracking, excessive wear, or seizure—the consequences are severe:

- Unplanned downtime across the production line

- Lengthy replacement process requiring heavy lifting, disassembly, and realignment

- Costs exceeding $100,000+ per hour in lost output (especially in mining or steel)

- Serious safety hazards, such as converter tipping or kiln collapse

Feel free to contact us for more information or assistance.