What are the advantages of gear shafts?

In the demanding worlds of mining, energy, and heavy industry, every component must endure relentless stress. The gear shaft stands as a quintessential example of engineering precision, serving as the robust backbone of power transmission systems. But what truly sets a superior gear shaft apart? This article delves into the fundamental benefits that make this component indispensable for operational success, exploring its design, resilience, and pivotal role across critical sectors.

1.Understanding the Gear Shaft: A Foundational Component

A gear shaft is far more than a simple metal rod. It is a meticulously engineered component designed to transmit torque and rotation, effectively acting as the central axle upon which gears are mounted. In applications ranging from colossal excavators to high-speed wind turbines, the gear shaft ensures that mechanical power is transferred smoothly and efficiently from the drive source to various working parts. Its performance is directly tied to the overall health, reliability, and output of the entire machinery system.

2.Unparalleled Advantages of a Premium Gear Shaft

Investing in a high-quality gear shaft delivers transformative benefits that resonate throughout your operations. Here are the key advantages that define its value.

2.1.Superior Power Transmission and Operational Efficiency

A precision-manufactured gear shaft minimizes energy loss during power transfer. Its precise geometry and balanced construction ensure optimal meshing with gears, reducing friction and vibrational harmonics. This translates directly into higher mechanical efficiency, allowing heavy machinery to achieve maximum output with lower energy input. The result is a smoother operation and significant long-term cost savings on power consumption.

2.2.Unmatched Durability and Extended Service Life

Industrial environments are punishing. Premium gear shafts are forged from high-grade alloys and undergo specialized heat treatments like carburizing or induction hardening. This process creates an incredibly hard, wear-resistant surface while maintaining a tough, shock-absorbing core. This enduring strength combats the primary failure modes of abrasion, pitting, and fatigue, drastically extending the component’s lifecycle and reducing costly, unplanned downtime.

2.3.Exceptional Load-Bearing Capacity and Resilience

The fundamental design of a gear shaft empowers it to handle immense torsional and bending stresses. Whether supporting the sudden, jarring loads in a mining crusher or the constant, heavy torque in a oil drill, a robust gear shaft maintains its structural integrity. This resilience ensures consistent performance under peak loads, safeguarding the entire gearbox assembly from catastrophic failure and enhancing workplace safety.

2.4.Precision Engineering for Reduced Maintenance

Tolerances matter. A gear shaft machined to exacting specifications ensures perfect alignment and reduces uneven wear on gears and bearings. This precision diminishes the need for frequent adjustments, lowers lubricant contamination, and simplifies overall maintenance schedules. The outcome is a more predictable, reliable machine with lower total cost of ownership over its operational lifespan.

3.Navigating Common Queries on Gear Shafts

3.1.What factors determine the correct material for a gear shaft?

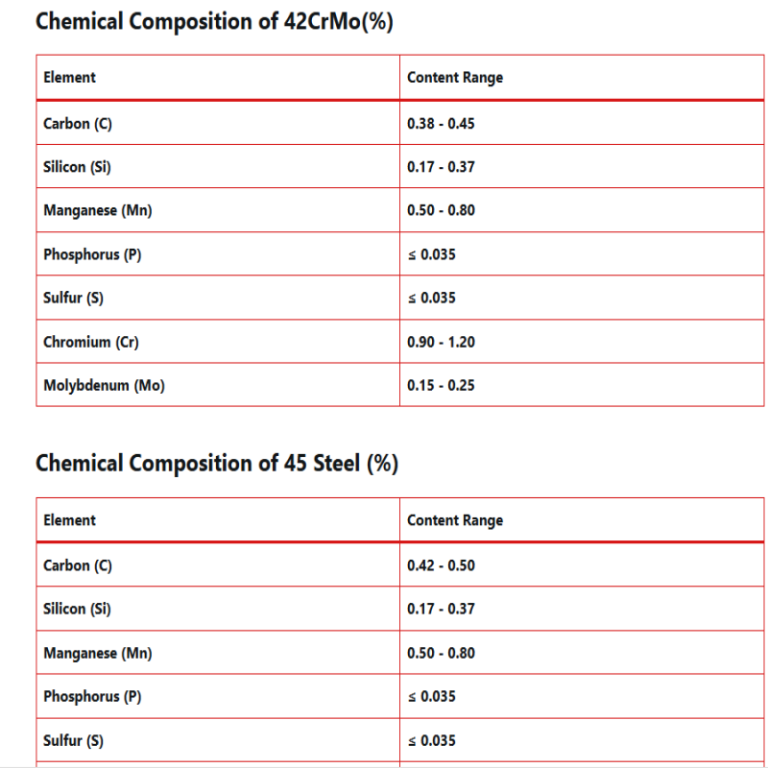

Material selection hinges on application demands. Common choices include high-strength alloy steels like AISI 4140 or 4340 for their superb toughness. For corrosive environments, stainless steel or specialized coatings may be applied. The key is balancing required hardness, core strength, and resistance to operational stresses.

3.2.How does proper heat treatment enhance a gear shaft’s performance?

Heat treatment is not an add-on; it is a core part of creating a high-performance gear shaft. Processes like through-hardening or case hardening tailor the material’s properties, creating a hard surface to resist wear while retaining a ductile core to absorb impact, preventing brittle fracture under shock loads.

4.Dominant Applications of Industrial Gear Shafts

The versatility and strength of the gear shaft make it a hero component across multiple heavy industries. Its design is adapted to meet the unique challenges of each sector.

The following table outlines key application scenarios:

| Application Sector | Machine/Equipment | Gear Shaft Function & Key Requirement |

| Mining & Minerals | Ball Mills, Crushers, Conveyors | Transmit extreme torque for crushing/grinding; Must withstand shock loads and abrasive dust. |

| Oil & Gas | Drilling Rigs, Pump Jacks, Compressors | Handle high-torque, continuous cyclic loads; Requires superior fatigue resistance. |

| Power Generation | Turbine Drives, Coal Pulverizers | Ensure precise, high-speed rotation for energy conversion; Demands balancing and heat resistance. |

| Wind Energy | Main Gearbox in Nacelle | Convert low-speed rotor rotation to high-speed generator input; Critical for durability & efficiency. |

| Heavy Manufacturing | Rolling Mills, Extruders | Support massive loads for metal/plastic forming; Needs exceptional bending strength. |

5.The Strategic Investment in Quality

The gear shaft is unequivocally more than a spare part; it is a strategic investment in your machinery’s heartbeat. Its advantages in transmitting power reliably, bearing immense loads, and providing enduring service directly dictate productivity, safety, and profitability. By specifying gear shafts engineered for your specific industrial challenges, you build a foundation of unwavering reliability for the most critical operations on Earth.

Feel free to contact us for more information or assistance.