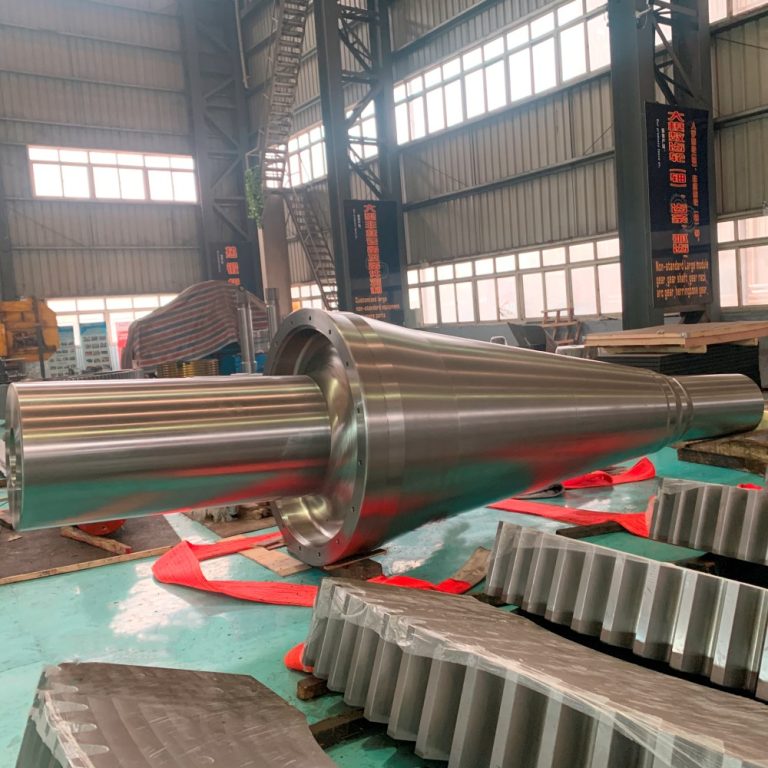

Luoyang Wangli Spline Shaft:”Precision Backbone” in Heavy-Duty Transmission

spline shafts are the key core for bearing power and transmitting precision. This spline shaft ingeniously crafted by Luoyang Wangli has become a “reliable backbone” in heavy-duty working conditions such as mining and metallurgy, demonstrating the technical height of Chinese industrial component manufacturing, by virtue of the in-depth application of materials science, the ultimate pursuit of precision machining technology and the innovative design of structural mechanics.

Material and Heat Treatment: The “Golden Ratio” of Strength and Toughness

To meet the severe challenges of heavy-duty alternating loads, this spline shaft selects high-quality alloy structural steel as the matrix. Through the combined heat treatment process of forging + quenching and tempering, not only the internal structure of the steel is uniformly refined, but also the “perfect balance of strength and toughness” is achieved – it not only has the hard strength to resist heavy-duty impact, but also has the fatigue resistance to adapt to dynamic loads. The hardness uniformity far exceeds the conventional industry standards, laying a solid material foundation for the reliable operation of the shaft.

Precision Machining: Defining the “Smoothness” of Transmission with Micron-Level Precision

In terms of transmission precision control, Luoyang Wangli engraves “precision” into every process:

- Spline Tooth Profile Machining: High-precision CNC gear hobbing machines are used, and the tooth surface roughness is strictly controlled below Ra1.6, and the cumulative tooth pitch error is less than 5μm, ensuring the “seamless docking” during gear meshing and realizing high-precision and low-noise transmission, making power transmission as smooth as a “fluid”.

- Axis and Coaxiality Control: The axis deviation of the splines at both ends is less than 0.1mm, ensuring the synchronism of multi-component transmission. After the shaft diameter is processed by “precision turning + grinding”, the coaxiality of each section of the shaft diameter is less than 0.03mm, and the flatness and perpendicularity errors of the mating surfaces are both controlled within 0.02mm. The concept of “high coaxiality” is implemented throughout the processing and assembly process, completely eliminating additional wear and power loss caused by eccentricity.

Structure and Performance: A “Tough Player” in Heavy-Duty Working Conditions

The contact area of the spline reaches more than 85%. This “wide-area contact” design can effectively disperse the load and greatly improve the wear resistance and impact resistance. In scenarios such as frequent starts and stops of mining machinery and heavy-duty alternations of metallurgical equipment, its fatigue life is more than 30% longer than that of traditional integral spline shafts, allowing the equipment to still operate stably for a long time under “high-pressure” working conditions, injecting “long-term power” for enterprises to reduce operation and maintenance costs and improve production efficiency.

Protection Upgrade: A “Durable Armor” in Harsh Environments

Aiming at the humid and dusty industrial environments such as mining and metallurgy, the shaft surface is treated with a special anti-corrosion and wear-resistant coating. The coating is tightly bonded and has a uniform thickness, which can not only resist the corrosion of water vapor and dust, but also maintain wear resistance during long-term friction. It allows the spline shaft to always be “armored” in the “test of harsh working conditions”, achieving a dual improvement in service life and reliability.

From material selection to heat treatment, from micron-level processing to structural optimization, this spline shaft of Luoyang Wangli is a masterpiece integrating materials science, precision manufacturing and engineering mechanics. It is not only a transmission shaft, but also a vivid example of China’s industrial components moving towards “high precision, advanced technology and sophistication”, providing a “reliable, efficient and long-lasting” solution for heavy-duty transmission systems in industries such as mining and metallurgy, and forging the core strength in the industrial field with technological innovation!

We mainly produce customized large mechanical spare parts according to customer drawings. If you are interested in our products or want to know more, please click the link to contact us.