How To Maximize Gear Shaft Efficiency in Industrial Machinery?

In the demanding worlds of mining, oil, power, and wind energy, operational efficiency is paramount. At the heart of countless heavy-duty machines lies a critical component whose performance dictates overall productivity: the gear shaft. Understanding how to maximize gear shaft efficiency is not just an engineering goal; it is a direct pathway to enhanced operational uptime, reduced energy consumption, and significant cost savings. This pivotal drive element transmits torque and motion, and its optimization impacts the entire mechanical system’s lifespan and output.

1.What is a Gear Shaft and Why is Its Efficiency Crucial?

A gear shaft is a rotating mechanical element designed to support gears, transmitting power and motion between components within a drive train. In industrial applications, its role transcends mere rotation; it is the backbone of power transmission. The quest for supreme gear shaft efficiency directly correlates to minimizing frictional losses, preventing catastrophic downtime, and ensuring relentless performance under extreme loads. An optimized gear shaft means your equipment works smarter, not harder, delivering formidable power where it’s needed most.

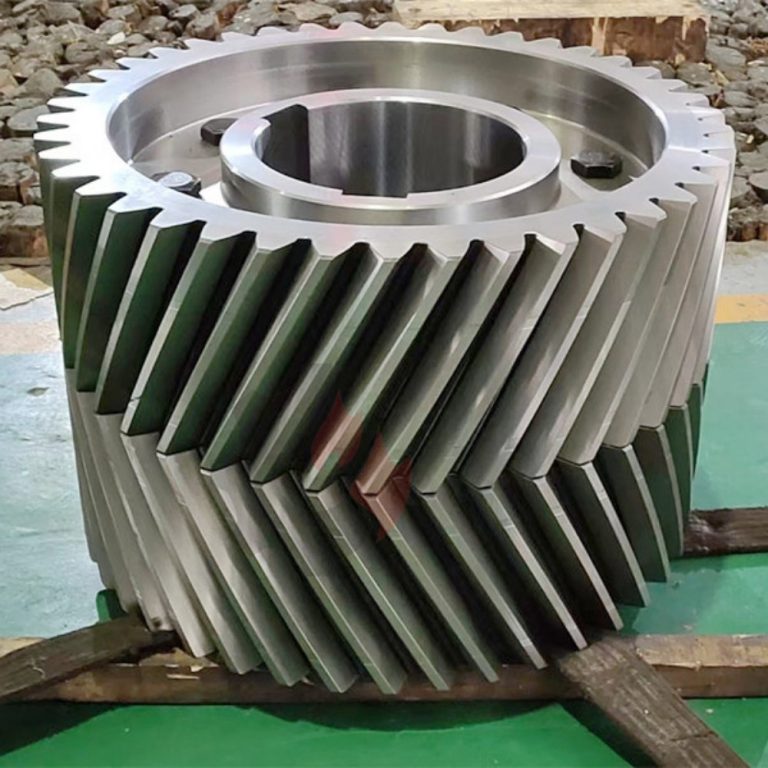

2.Unveiling Our High-Performance Gear Shaft Solution

Our engineered gear shaft product line is conceived for industrial supremacy. We specialize in manufacturing robust, custom-designed gear shafts that meet the rigorous specifications of sectors where failure is not an option. These are not mere components; they are the culmination of advanced metallurgy, precision machining, and rigorous testing. Our gear shaft solutions are synonymous with reliability, crafted to become the indefatigable core of your most critical machinery, ensuring seamless power flow from source to application.

3.The Defining Features of an Elite Gear Shaft

The journey to peak gear shaft efficiency is anchored in its fundamental features. Superior design and execution are non-negotiable.

3.1.Precision Engineering for Optimal Load Distribution

Every gear shaft we produce undergoes meticulous design analysis. Advanced modeling ensures perfect load distribution across the shaft’s length and at gear interfaces. This precision engineering mitigates stress concentrations—a common antagonist of efficiency—leading to smoother operation, reduced vibration, and a dramatic extension in service life for both the shaft and its mating components.

3.2.Advanced Material Science for Resilience

The soul of a durable gear shaft is its material. We employ alloy steels and specialized treatments, such as carburizing or induction hardening, to achieve an exceptional balance of core toughness and surface hardness. This material mastery grants our gear shafts a formidable resistance to wear, pitting, and fatigue, allowing them to thrive in abrasive mining environments or under the constant torque fluctuations of a wind turbine.

3.3. Superior Surface Finish and Heat Treatment

A gear shaft’s surface quality is a critical yet often underestimated factor in efficiency. Our manufacturing process delivers an exceptionally smooth surface finish, drastically reducing friction and heat generation. Coupled with controlled heat treatment processes, this ensures dimensional stability and preserves the integrity of the gear shaft’s microstructure under thermal stress, locking in performance over time.

4. Practical Applications: Where Our Gear Shaft Excels

The true test of a gear shaft’s efficiency is its performance in the field. Our components are engineered for mission-critical applications.

- Mining Machinery: In crushers, conveyors, and excavators, our gear shafts withstand immense shock loads and particulate contamination, ensuring continuous material handling.

- Oil & Gas Equipment: From pump drives to drilling rigs, our shafts offer reliable performance in remote, high-torque applications, resisting corrosive elements.

- Power Generation: In coal, gas, or hydro turbines, the precision of our gear shaft contributes to stable, high-speed rotation for consistent power output.

- Wind Energy: Inside gearboxes perched hundreds of feet in the air, our gear shafts are built for reliability, minimizing maintenance cycles and maximizing energy harvest.

5.How to Select the Right Gear Shaft for Maximum Efficiency

Selecting the optimal gear shaft is a strategic decision. To maximize efficiency, consider these pillars: Load Analysis (understanding torque, bending moments, and shock loads), Operational Environment (exposure to heat, chemicals, or abrasives), Geometric Compatibility (precise fit with existing gears and bearings), and Manufacturing Quality (the assurance of precision tolerances and treatments). Partnering with a specialist who can navigate these parameters is the ultimate secret to unlocking unparalleled gear shaft efficiency.

| Industry Sector | Specific Machinery / Application | Critical Role of the Gear Shaft |

|---|---|---|

| Mining | Crushers, Conveyors, Excavators | Withstands immense shock loads and abrasive particulate contamination to ensure continuous, reliable material handling. |

| Oil & Gas | Pump Drives, Drilling Rigs | Provides reliable high-torque power transmission in remote and often corrosive operational environments. |

| Power Generation | Coal, Gas, and Hydro Turbines | Ensures stable, high-speed rotation within turbines for consistent and efficient power output. |

| Wind Energy | Gearboxes inside Wind Turbines | Designed for maximum reliability and durability at great heights to minimize maintenance and maximize energy harvest. |

6.The Strategic Advantage of an Optimized Gear Shaft

Ultimately, a high-efficiency gear shaft is a linchpin of industrial profitability. It is an investment in relentless performance and operational calm. By focusing on precision engineering, advanced materials, and application-specific design, you can transform this core component from a potential point of failure into a powerhouse of productivity. Choose a gear shaft engineered not just to meet specifications, but to redefine the efficiency boundaries of your machinery.

Feel free to contact us for more information or assistance.