Helical Gear Shaft: About Hardness Testing

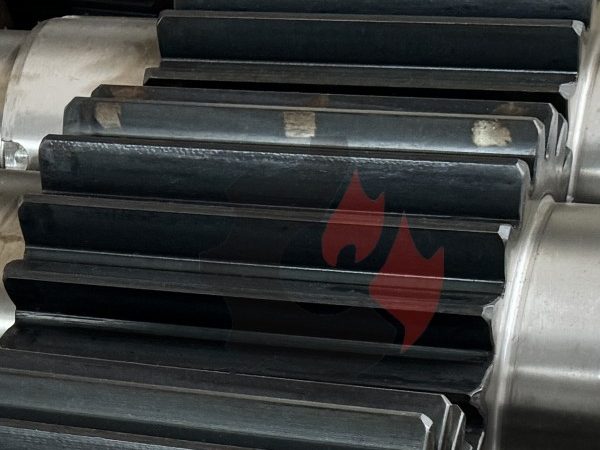

When a helical gear shaft transmits thousands of tons of torque amid the roar of mining machinery, resists strong wind loads in a wind power gearbox, and endures the dual pressure of high temperature and heavy load on a metallurgical rolling mill, the core that supports it through extreme working conditions is the hard hardness of its tooth part and shaft body. The three key testing points at the gear position are precisely customized “precision scales” for this layer of “steel armor” — from the meshing area of the tooth surface to the stress-concentrated area of the tooth root, and then to the transition connection area of the shaft shoulder. Through precise control of hardness, it fundamentally ensures the wear resistance, fatigue resistance, and long-term service capability of the helical gear shaft under heavy-load, high-impact, and complex environments.

1.Hardness: The “Durability Gene” of Helical Gear Shafts and the Core of Rigid-Toughness Balanced Design

For helical gear shafts that bear heavy loads, high-frequency impacts, and even complex environments (such as dust and low temperature), hardness is not “the higher the better”, but a core indicator that “accurately matches working conditions”. The hardness difference between the surface and the core is even the key contradiction that determines “durability”.

Surface Hardness serves as a “Wear-Resistant Shield” customized for working conditions. The tooth surface needs to be strengthened through targeted heat treatment processes. For heavy-load mining scenarios, “carburizing + quenching” is commonly used to make the surface hardness reach 58–62 HRC (Rockwell Hardness C Scale), forming a 1.5–2 mm thick wear-resistant layer to resist the scratch and wear of coal gangue and ore particles on the tooth surface. For high-precision wind power scenarios, “gas nitriding” is adopted, which increases the surface hardness to 850–1000 HV (Vickers Hardness, equivalent to over 65 HRC) with a deformation of only 0.01 mm, balancing wear resistance and transmission accuracy. For low-temperature wind power scenarios (such as minus 30°C in northern China), the surface hardness is appropriately reduced to 56–58 HRC to avoid excessive brittleness leading to tooth surface chipping.

Core Hardness functions as a “Tough Support” against impacts. The core of the shaft body needs to maintain moderate hardness, usually controlled at 30–40 HRC (corresponding to a tensile strength of 800–1000 MPa). If the core is too hard (e.g., over 45 HRC), the shaft body will have insufficient toughness, and the tooth root is prone to brittle fracture under heavy load; if the core is too soft (below 28 HRC), it cannot support the surface wear-resistant layer, leading to “surface spalling” failure. This hardness gradient of “hard exterior and tough interior” is like putting a “rigid armor + flexible lining” on the gear shaft, making it both wear-resistant and impact-resistant.

2.Three-Point Hardness Testing: A “Layered Durability Test” for Gear Shafts to Control Quality Without Dead Ends

The three testing points at the gear position are not randomly selected, but designed for the “failure-prone areas” of the helical gear shaft during actual operation, realizing “full-dimensional screening” of hardness performance.

The Tooth Surface Testing Point targets the core meshing area to eliminate “wear failure”. The testing position is selected in the middle of the tooth surface (avoiding the tip of the tooth top and the transition arc of the tooth root), which is the main stress-bearing area during gear meshing. The hardness must strictly meet the working condition standards. For example, if the tooth surface hardness of a mine scraper conveyor gear shaft is lower than 58 HRC, the tooth surface will be “thinned” after only 3 months of operation, leading to increased transmission clearance and abnormal noise; while qualified products can operate continuously for 18–24 months, with the wear amount controlled within 0.1 mm. During testing, a Rockwell hardness tester (Model HR-150A) is used to take 3 measuring points evenly on the tooth surface, and the average value is taken as the final result, with a deviation of ≤ 2 HRC.

The Tooth Root Testing Point focuses on the stress-concentrated area to prevent “fatigue fracture”. The tooth root is the “mechanical weak area” of the shaft body — the bending stress borne by the tooth root during meshing is 3–5 times that of the tooth surface, and fatigue cracks are prone to occur after long-term operation. Therefore, the tooth root hardness needs to be controlled at 45–50 HRC, which not only has sufficient hardness to resist crack initiation but also is not too hard to cause loss of toughness. During testing, a portable hardness tester (Model TH110) is used to fit the tooth root arc surface (radius ≥ 5 mm). If the hardness is lower than 45 HRC, the gear shaft is prone to “stress cracks” at the tooth root during heavy-load startup (such as the full-load startup of mining machinery), and severe cases may lead to fracture within 1 month.

The Shaft Shoulder Transition Testing Point guards the key connection area to avoid “stress cracking”. The shaft shoulder is the transition part between the gear and the journal, where the sudden change in diameter is prone to stress concentration, and it also needs to bear the radial load transmitted by the gear. The hardness here needs to form a “smooth transition” with the core, usually controlled at 35–42 HRC, with a deviation not exceeding 3 HRC. If the shaft shoulder is too hard (e.g., over 45 HRC), a “hardness step” will form with the core, and “cracking” is prone to occur at the root of the shaft shoulder under heavy load; if it is too soft (below 35 HRC), the strength will be insufficient, leading to “plastic deformation” of the shaft shoulder and axial movement of the gear.

3.The “Industrial Value” of Hardness Testing: Reliable Transmission from Workshop Quality Control to On-Site Durability

Helical gear shafts that have undergone three-point hardness testing are not only “qualified products” but also “durable parts adapted to working conditions”, and their value has been continuously verified in different industrial scenarios.

In mining scenarios, wear-resistant and durable helical gear shafts can maintain undiminished tooth surface hardness under the continuous impact of coal gangue (impact force up to 50 kN) and dusty wear environment. Their service life is 30%–50% longer than that of ordinary untested gear shafts, reducing 2–3 shutdown replacements for mines every year and directly cutting operation and maintenance costs by over one million yuan.

In wind power scenarios, cold-resistant and impact-resistant helical gear shafts serve stably for more than 15 years in gearboxes operating at minus 30°C in northern China. Through precise hardness control (surface hardness 56–58 HRC, core hardness 35–40 HRC), they resist strong wind loads (instantaneous torque up to 200 kN·m) and low-temperature embrittlement risks, far exceeding the industry’s average service life of 10 years.

In metallurgical scenarios, high-temperature and heavy-load resistant helical gear shafts operate without failure for 3 consecutive years in hot rolling mills. These gear shafts bear high temperatures (ambient temperature 80°C) and heavy rolling loads (radial load up to 80 kN). Through “nitriding treatment + three-point testing”, the surface hardness remains above 850 HV, and the shaft shoulder hardness is 38–42 HRC, avoiding shutdowns of the rolling mill caused by gear shaft failure (each hour of shutdown results in a loss of over 100,000 yuan).

Hardness testing also provides a key basis for “quality traceability”. Each testing point records “testing time, operator, hardness value, and equipment number”. If the gear shaft fails later, the testing data can be traced to quickly determine whether it is “substandard hardness” or “unexpected working conditions”, providing direction for subsequent product optimization.

The three hardness testing points of the helical gear shaft represent the ultimate control of “material performance” in industrial manufacturing. They are not just about testing hardness, but reflect a precise design that matches working conditions and prevents failures. This logic of “hard exterior and tough interior + regional testing” turns each gear shaft into an “industrial warrior with balanced rigidity and toughness” — the surface is as wear-resistant as armor, the core is as impact-resistant as a ligament, and the shaft shoulder connects like a joint. This not only constitutes the “technical confidence” of China’s high-end equipment component manufacturing but also serves as a key bargaining chip for industrial equipment to achieve “durability breakthrough” in global competition.

We mainly produce customized large mechanical spare parts according to customer drawings. If you are interested in our products or want to know more, please click the link to contact us.