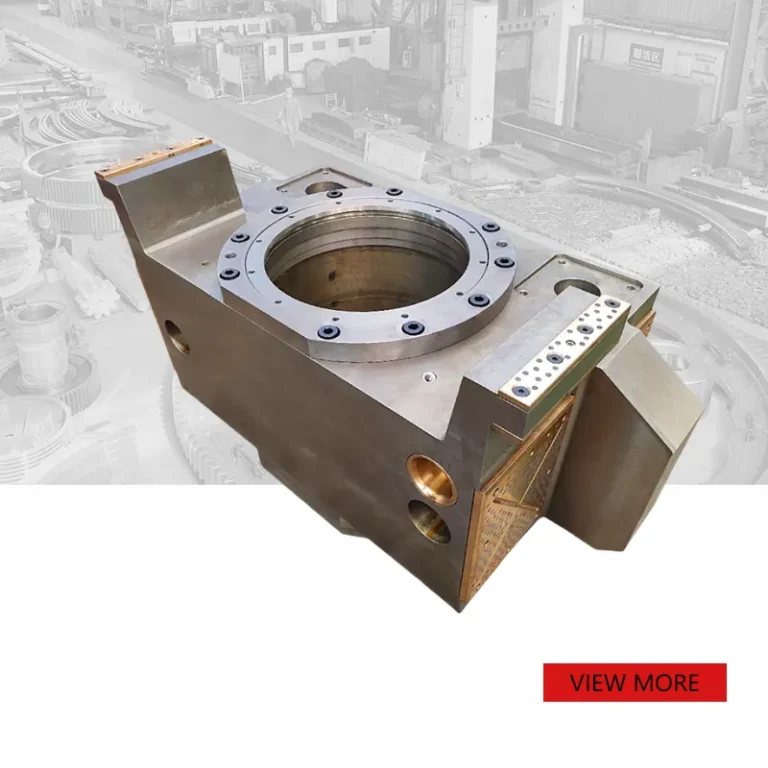

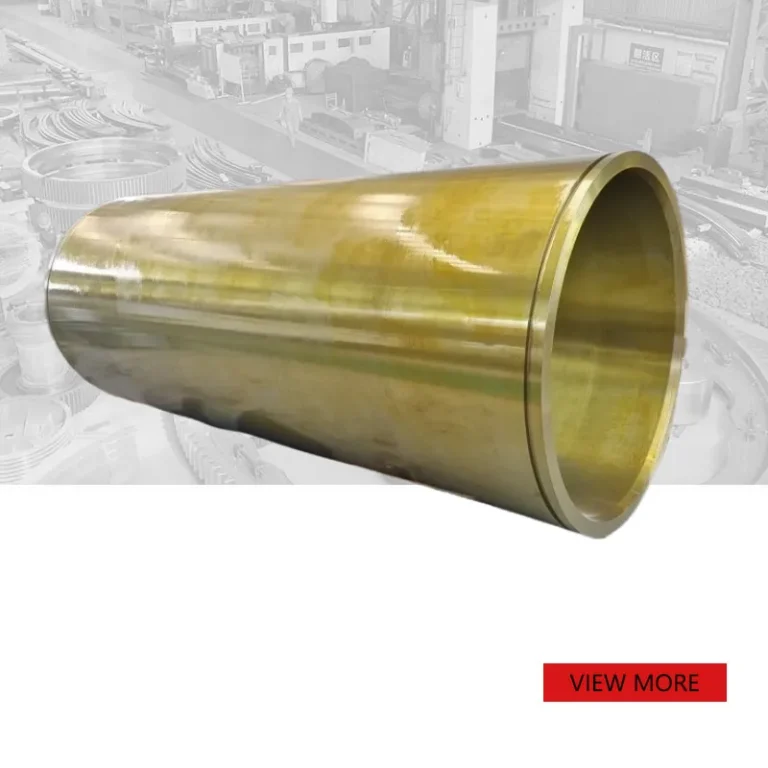

Large non-standard customized metal molds for Industry

PRODUCT PARAMETERS

Description

Large non-standard customized metal molds for automotive, aerospace, and mining industries are specifically designed to meet the demands of high-precision, high-strength, and complex component manufacturing. Utilizing high-quality tool steel (e.g., H13, SKD61) and precision CNC machining combined with heat treatment processes, these molds ensure dimensional tolerances strictly controlled within ±0.01mm while achieving wear resistance, impact resistance, and extended service life. They are widely applied in the efficient production of automotive body panels, aerospace structural components, and mining machinery housings, serving as core “mother machine”-grade tooling equipment indispensable to high-end manufacturing sectors.

1.Material Preparation and Inspection

1.1 High-performance tool steels (e.g., H13, SKD61) or specialized alloys are selected per drawings.

1.2 Materials undergo hardness testing, chemical composition analysis, and pre-treatment to meet requirements for strength and wear resistance.

2.Precision Machining and Heat Treatment

2.1 Rough Machining: Large CNC milling machines remove bulk material efficiently.

2.2 Heat Treatment: Hardness (HRC48–52) and toughness are achieved via quenching and tempering.

2.3 Finish Machining: Five-axis machining centers perform high-precision milling and CNC grinding, ensuring dimensional tolerances within ±0.01mm.

2.4 Surface Treatment: Polishing, nitriding, or PVD coating enhance wear resistance and surface finish (Ra≤0.2μm).

3.Assembly and Precision Calibration

3.1 Components (e.g., guide pillars, ejector mechanisms) are assembled strictly according to customer drawings.

3.2 CMM (Coordinate Measuring Machine) verifies assembly clearances and ensures motion components operate smoothly with dimensional consistency ≤0.005mm.

4.Trial Run and Process Optimization

4.1 A trial stamping is conducted on a test press using production-grade materials.

4.2 Part dimensions, surface quality, and forming stability are evaluated. Parameters like blank holder force and stamping speed are fine-tuned to optimize efficiency.

5.Final Inspection and Delivery

Full dimensional checks (including geometric tolerances), durability testing (≥500,000 stamping cycles), and customer approval ensure compliance with high-precision, high-reliability standards before delivery.

About Us

More than 80% reason of mechanical parts’ working life depends on hot processing (steel making, forging/casting , welding, heat treatment). Our eight metal material experts form a team to control our raw material’s internal quality and mechanical properties from the source,in this way to improve our products’ service life.

Feel free to contact us for more information or assistance.