How to Forge Gears?

In the demanding worlds of mining, power generation, and heavy industry, the question isn’t merely “how to forge gears,” but how to forge gears that endure. The process of forging is the foundational alchemy that transforms raw steel into the relentless heart of machinery. This article delves into the precision engineering behind forged industrial gears, exploring why their superior integrity is non-negotiable for critical applications in oil, gas, wind, and electrical sectors. Discover the journey from billet to powerhouse component.

1.The Critical Foundation: What Does It Mean to Forge a Gear?

Forging a gear is a metallurgical imperative, not just a manufacturing step. Unlike casting or machining from bar stock, forging involves the strategic deformation of heated alloy steel under immense pressure. This process meticulously aligns the metal’s grain flow to the contour of the gear tooth profile. The result is a continuous grain structure that follows the shape of the gear, eliminating weak points and porosity. This foundational method is why forged gears are the undisputed choice for high-torque, high-shock-load environments where failure is not an option. The forged gear blank becomes a monolithic entity, primed for resilience.

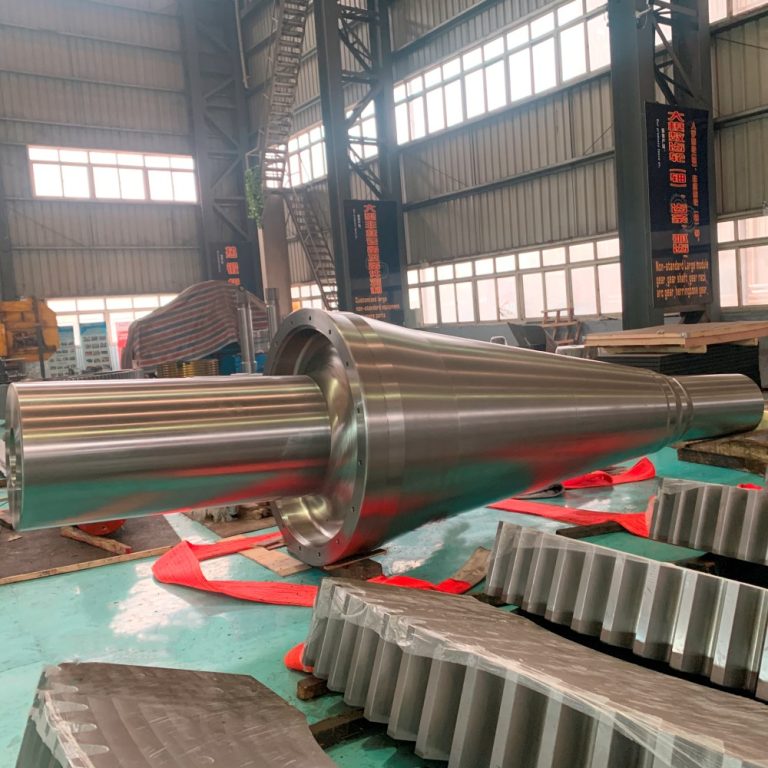

2.Our Product Overview: Engineered Forged Gear Solutions

We specialize in the design and production of custom, heavy-duty forged gears for mission-critical industrial applications. Our product line encompasses a vast range of sizes and configurations, from large-diameter rotary kiln gears for mining to high-precision, high-speed gears for wind turbine gearboxes and turbine-driven compressor sets. Each gear begins as a certified, high-grade alloy steel, subjected to our controlled forging process to ensure a homogeneous internal structure. We don’t just make gears; we forge the backbone of industrial productivity, ensuring every tooth can transmit power with absolute reliability under the most severe operating conditions.

3.The Unmatched Advantages of a Forged Gear

Why does the forged gear consistently outperform? The benefits are embedded in its very microstructure.

Superior Strength & Fatigue Resistance: The forged grain flow creates a gear with exceptional yield strength and toughness. It can withstand repetitive, heavy shock loads—common in crushers or mining excavators—without developing cracks, offering an unparalleled safety factor and lifespan.

Enhanced Reliability in Harsh Environments: For applications in oil fields or offshore wind farms, where equipment faces corrosion and extreme weather, the denser, non-porous structure of a forged gear provides a more reliable barrier against environmental degradation and stress corrosion cracking.

Optimal Metallurgical Consistency: The forging process ensures uniform chemical composition and mechanical properties throughout the entire gear blank. This consistency is critical for subsequent heat treatment, guaranteeing even hardness and wear characteristics across every tooth of the final gear.

4.Technical Deep Dive: The Forging and Finishing Process

Our “how to forge gears” protocol is a symphony of precise steps.

4.1.Material Selection & Billet Heating: We start with meticulously sourced alloy steel. The billet is uniformly heated to a precise forging temperature in computer-controlled furnaces.

4.2.Precision Forging: Using powerful hydraulic presses, the heated steel is forged into a near-net-shape gear blank. This stage is where the critical grain flow orientation is established.

4.3.Annealing & Rough Machining: The forged blank is annealed to relieve internal stresses and then rough-machined to prepare for heat treatment.

4.4.Heat Treatment (Hardening): The gear undergoes controlled hardening (e.g., carburizing, quenching, and tempering) to achieve the specified surface hardness and core toughness, creating a gear that is hard on the outside yet tough on the inside.

4.5.Precision Finishing: The final steps include precision gear hobbing or grinding to achieve the exact tooth profile, lead, and surface finish. This ensures perfect meshing and quiet, efficient power transmission in the final assembly.

5.Application Spectrum: Where Forged Gears Are Indispensable

Forged gears are the driving force in industries where downtime costs millions. The following table outlines key application scenarios:

| Industry/Sector | Typical Application | Gear Type | Core Requirement Met by Forging |

| Mining & Mineral Processing | Rotary Kilns, Ball Mills, Crushers, Draglines | Large Spur & Helical Gears, Herringbone Gears | Extreme shock load resistance, wear longevity |

| Oil & Gas | Drilling Rigs, Mud Pumps, Compressor Trains, Pumps | High-Speed Pinions, Heavy-Duty Drive Gears | High torque capacity, reliability in remote/offshore settings |

| Power Generation | Coal/Gas Turbine Drives, Cooling Tower Fans, Hydro Turbines | Turbine Drive Gears, Large Fan Gears | High rotational stability, fatigue resistance for 24/7 operation |

| Wind Energy | Main Gearbox (Planetary & Helical Stages) | Planetary Gear Sets, Helical Gears | Exceptional fatigue life to handle variable wind loads |

| Heavy Manufacturing | Steel Mill Roll Drives, Ship Propulsion | Spur Gears, Worm Gears | Ability to handle immense, fluctuating torque loads |

6.Addressing Common Questions on Gear Forging

Q: Isn’t a machined gear sufficient for heavy industry?

A: While machined gears have their place, forged gears offer a fundamental advantage in severe-duty applications. Machining cuts through the natural grain structure, potentially creating stress risers. Forging contours the grain, providing a inherent strength advantage that machining cannot replicate, especially in the root of the gear tooth where stress is highest.

Q: How does forging impact the long-term total cost of ownership?

A: Significantly. The initial investment in a premium forged gear is offset by its dramatically extended service life and reduced risk of catastrophic failure. In industries like mining or offshore wind, where replacement costs and downtime are astronomical, the forged gear’s reliability translates directly into lower total cost and superior operational economics.

Q: Can you forge custom gear designs for specific applications?

Absolutely. Our expertise lies in tailoring the forging process and metallurgy to your specific needs. Whether you require a unique tooth profile for a legacy machine, special material grades for corrosive environments, or specific hardening protocols, we engineer the forging solution to match your exact operational gear requirements and performance goals.

7.The Forged Difference in Power Transmission

Understanding “how to forge gears” reveals the profound difference between a simple component and an engineered pillar of reliability. In the relentless environments of mining, power, and energy, the choice is clear. A forged gear is not merely a part; it is a commitment to uninterrupted operation, safety, and productivity. It represents the synthesis of material science, precise engineering, and a deep understanding of industrial challenges—forging not just metal, but trust and performance into every revolution.

Meta Description: Discover how to forge industrial gears for mining, oil, power & wind sectors. Learn about the advantages, process, and applications of premium forged gear solutions for unmatched durability.

Feel free to contact us for more information or assistance.