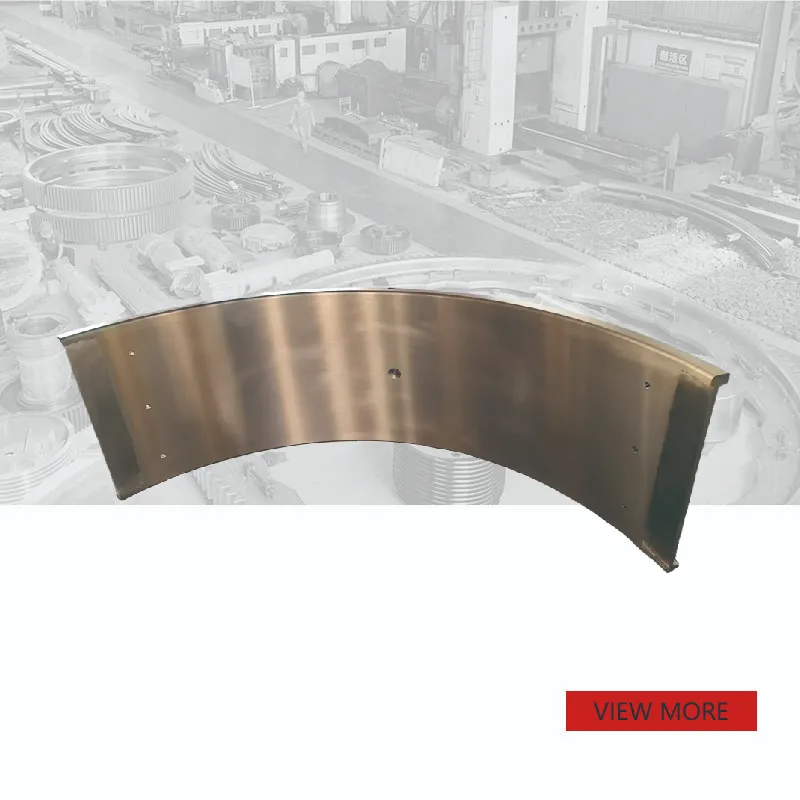

High-Strength Segmented Copper Bushing for Kilns

PRODUCT PARAMETERS

Description

In industries such as cement, metallurgy, and chemicals, the contact surface between the roller bearing and the riding ring in kiln systems is a critical “joint” that withstands immense loads and continuous friction. Traditional monolithic bronze bushings are inconvenient to install, dismantle, and maintain. Localized wear often necessitates full replacement, leading to high costs. Our segmented bronze bushings, crafted from premium high-strength brass (ZCuAl10Fe3) or tin bronze (ZQSn10-1/ZQAl9-4), offer a precision casting solution. Through scientific segmented design, they seamlessly replace traditional bushings, significantly enhancing equipment maintainability and operational stability.

Segmented Copper Bushing of Manufacturing Process:

1.Casting:

Melting: Medium-frequency induction electric furnaces melt the alloy at precisely controlled temperatures (1150°C–1200°C) to ensure metal purity and optimal fluidity.

Casting Process: Metal mold or centrifugal casting minimizes defects (e.g., porosity, shrinkage), yielding a dense, uniform microstructure with superior mechanical properties.

2.Heat Treatment:

Stress-relief annealing for ZCuAl10Fe3 alloys (600°C–650°C, followed by slow cooling) eliminates internal casting stresses to prevent deformation during machining or operation.

3.Rough Machining:

Initial Shaping: Heavy-duty CNC lathes perform rough turning on outer diameters, end faces, and inner bores, removing excess material.

Segmented Machining: Each segment is processed individually to ensure dimensional consistency.

4.Precision Machining:

Inner Bore Finishing: High-precision CNC lathes or boring mills ensure tight tolerances for optimal clearance with the roller shaft.

Outer Diameter Finishing: Meets interference/transition fit requirements with the roller hub for reliable load transmission.

Interface Machining: Precision milling or wire-cutting ensures seamless contact between segments, with interface gaps ≤0.05mm to prevent uneven stress.

Lubrication Features: Circumferential oil grooves or oil holes are milled/drilled on the inner bore to ensure even lubricant distribution and effective oil film formation.

5.Surface Treatment & Deburring:

Edge Smoothing: All sharp edges are deburred to prevent shaft damage during installation.

Cleaning: Oil residues and metal debris are removed to ensure surface cleanliness.

6.Final Inspection & Packaging:

Dimensional Verification: Critical dimensions are checked with precision measuring tools.

Inspection: Confirms absence of cracks, porosity, or scratches.

Anti-Rust Protection: Bushings are coated with rust inhibitor, wrapped in moisture-proof film, and securely packed in reinforced wooden crates for safe transport.

Optimal Copper Bushing Material Selection Guide for Industrial Machinery

1. Tin Bronze Copper Bushing (e.g., ZCuSn10P1)

Ideal for heavy-load, high-speed applications

- Key Features: High hardness and wear resistance.

- Recommended Use: Cement kilns, metallurgical rollers, and machinery requiring 20 MPa load capacity at 8 m/s sliding speed.

- Performance Benefits: Outperforms standard copper alloys in continuous high-stress environments, reducing wear-related failures by up to 40%.

2. Aluminum Bronze Copper Bushing (e.g., ZCuAl9Fe4)

Engineered for harsh, corrosive environments

- Key Features: Superior strength and chemical resistance.

- Recommended Use: Marine systems, chemical processing plants, and offshore equipment exposed to seawater or corrosive agents.

- Performance Benefits: Prevents degradation in aggressive conditions, extending service life by 30%+ in chemical plants.

3. High-Lead Brass Copper Bushing (e.g., ZCuZn25Al6Fe3Mn3)

Designed for extreme shock and impact loads

- Key Features: Tensile strength ≥540 MPa with exceptional fatigue resistance.

- Recommended Use: Mining equipment, construction machinery, and industrial presses subjected to cyclic impact forces.

- Performance Benefits: Minimizes deformation under heavy shock loads, reducing failure risk by 50% compared to conventional materials.

4. Graphite-Embedded Copper Bushing

Self-lubricating technology for oil-free operation

- Key Features: Eliminates external lubrication needs through integrated graphite.

- Recommended Use: Automotive steering systems, food processing lines, and cement kilns with limited lubrication access.

- Performance Benefits: Extends service life by 100%+ versus standard copper bushings in dry conditions while reducing friction by 30%.

Feel free to contact us for more information or assistance.