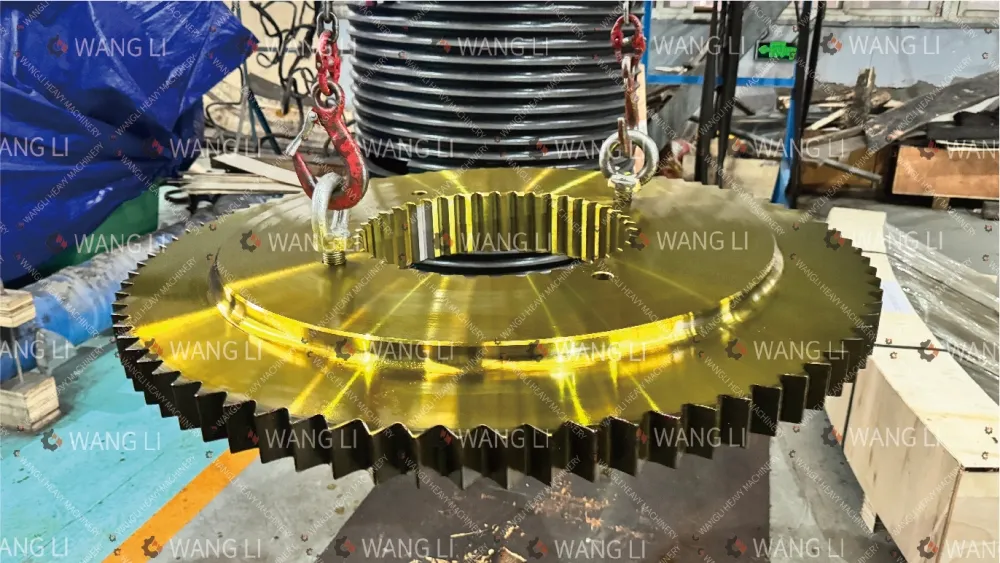

Wear-Resistant, High-Performance sprocket wheel for Global Mining Operations

PRODUCT PARAMETERS

Description

Selection of sprocket wheel Materials

| Mine Environment | Best Material | Why It Wins |

|---|---|---|

| General Coal Conveyors | 42CrMo | Balanced strength & cost – ideal for most mines |

| High-Impact Ore Processing | 20CrMnTi | Highest tooth hardness – survives crushing cycles |

| Acidic/High-Humidity Mines | ZG40CrNiMo | Prevents corrosion – no rust in wet tunnels |

| Budget Projects | QT800-2 Ductile Iron | Low cost, high vibration damping |

1.Design

- Mine-Specific Parameters: Define tooth count, pitch, and diameter for mining conveyors, excavators, or hoists.

- Precision CAD Models: Strict tolerances and wear-resistant surface specs.

- Material Selection: Exclusive mining-grade alloys (42CrMo, 20CrMnTi, ZG40CrNiMo).

2.Forging Process

Defect Detection: Ultrasonic testing (UT) on all blanks.

Closed-Die Forging: Optimizes metal flow → 30% higher fatigue strength for mine vibrations.

3.Heat Treatment of sprocket wheel

Critical for mines: Prevents wear from abrasive ore/coal.

Core Hardening: Quenching & tempering (HB260–300) for impact resistance.

Tooth Surface Hardening:

Carburizing: 1.5–2.0mm case depth, HRC58–62 tooth hardness.

4.Precision Machining of sprocket wheel

Dynamic balancing for high-speed conveyor systems.

Tooth Cutting: CNC hobbing for seamless chain meshing.

Critical Finishing:

Grinding → reduces vibration.

5.Surface Treatment & Packaging

Custom anti-rust protection & secure packaging: We apply corrosion-resistant coatings and use durable plywood cases, tailored to your product’s size, weight, and shipping needs.

Key Features

1.30% Longer Service Life – Advanced surface hardening resists abrasive wear in coal/ore transport.

2. Zero Unplanned Downtime – Reinforced teeth withstand 24/7 heavy loads & frequent starts.

3. Corrosion-Proof in Humid Mines – Specialized coating protects against sulfuric acid & moisture.

4. Seamless Compatibility – Fits all major scraper conveyors, tunneling machines & hoists.

Feel free to contact us for more information or assistance.