Double Helical Gear Shaft: Is It the Right Solution for Your High-Power Needs?

In the world of high-power mechanical transmission, the double helical gear shaft stands out as an engineering masterpiece. Designed to overcome the limitations of single helical gears, this component is crucial for applications demanding immense power and exceptional smoothness.

1.Understanding the Double Helical Gear Shaft

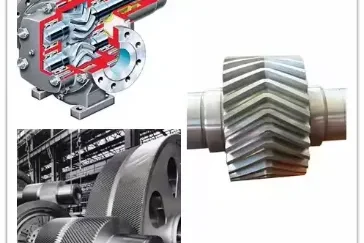

A double helical gear shaft is an integral component consisting of a shaft and gears that feature two opposing sets of helical teeth. These teeth are arranged in a “V” shape, often referred to as a herringbone pattern. This ingenious design is fundamentally aimed at solving one of the primary drawbacks of its single helical counterpart: axial thrust.

1.1 Key Advantages of the Double Helical Gear Shaft

The unique architecture of the double helical gear shaft provides several compelling benefits that make it indispensable in heavy-duty industries.

1.1.1 Superior Smoothness and Quiet Operation

The helical teeth design allows for a gradual engagement process. As one tooth begins to contact, the load is transferred smoothly across the face of the tooth. This continuous, sliding contact significantly reduces vibration and noise compared to spur gears, making the double helical gear shaft ideal for applications where operational quietness is critical.

1.1.2 Exceptional Load-Carrying Capacity

Imagine distributing a heavy weight over a wide platform versus a single point—the principle is similar. The dual-helix design of a double helical gear shaft effectively doubles the contact area between the meshing gears compared to a single helix. This wider face contact allows the gear to distribute the immense forces of transmitted torque and power much more evenly across the teeth. The result is a component capable of handling staggering loads found in steel rolling mills or large ship propulsion systems, all while minimizing surface wear and the risk of catastrophic tooth failure.

1.1.3 Balanced Axial Thrust: The Core Benefit

This is the most significant and defining advantage. A single helical gear, while smooth-running, generates a powerful and destructive axial force that pushes the gear along its shaft. This force mandates the use of massive, expensive thrust bearings to hold the system in place, adding complexity and energy loss. The double helical gear shaft provides an elegant, self-contained solution. Its two sets of opposing helices are masterfully engineered to generate equal and opposite axial thrust forces. These forces cancel each other out internally, creating a state of equilibrium. This neutralization of axial load simplifies bearing selection, reduces frictional losses, and dramatically enhances the overall mechanical efficiency and service life of the entire drive train. It is this ingenious self-balancing act that truly sets the double helical gear shaft apart.

2. Notable Disadvantages of the Double Helical Gear Shaft

Despite its impressive performance, the double helical gear shaft is not a universal solution and comes with its own set of challenges.

2.1Complex and Costly Manufacturing

Creating the precise herringbone tooth profile on a double helical gear shaft is a complex process. It requires specialized, often expensive, machinery and highly skilled labor. The machining, heat treatment, and finishing processes are more time-consuming and intricate than those for simpler gear types, leading to a higher unit cost.

2.2Design and Maintenance Challenges

The very feature that eliminates axial thrust—the central groove between the helices—can pose a challenge. It creates a natural trap for cutting debris during manufacturing and requires careful design to allow for thermal expansion. Furthermore, these gears cannot be disassembled axially like some others, complicating assembly and maintenance procedures in certain configurations.

| Application Field | Specific Equipment | Core Function & Value |

|---|---|---|

| Marine and Offshore Engineering | Main Propulsion Systems, Large Ship Gearboxes | Transmits massive engine torque to propellers, balances axial thrust, and ensures smooth, low-vibration navigation. Critical for large tankers and container ships. |

| Energy & Power Generation | Steam Turbines, Gas Turbines, Hydro Turbines, Wind Turbines | Enables stable high-speed power transmission between turbines and generators. High reliability and smooth operation are vital for grid stability. |

| Heavy Metallurgical Equipment | Rolling Mills, Metal Mill Main Gearboxes | Withstands extreme impact loads and rolling forces. Superior load capacity and durability ensure uninterrupted continuous production lines. |

| Mining & Construction Machinery | Ball Mills, Rotary Kilns, Large Crushers | Provides high-torque transmission under dusty, heavy-duty conditions to drive large rotating cylinders. Fundamental to equipment reliability. |

| Chemical & Compressor Systems | Centrifugal Compressors, Large Pump Units | Used in high-speed gearboxes. Its smooth, shock-free operation ensures compressor rotor stability and prevents surge in critical processes. |

2. Conclusion: A Powerful Solution for Specific Needs

In summary, the double helical gear shaft is not a one-size-fits-all component but a precision-engineered solution for the most demanding power transmission challenges. Its superior performance—characterized by unparalleled smoothness, exceptional load capacity, and the self-balancing elimination of axial thrust—makes it the undisputed champion in applications where failure is not an option. From the relentless power of a marine propulsion system to the critical spin of a turbine generator, the double helical gear shaft ensures reliability, efficiency, and quiet operation.

However, this superior performance comes with a clear cost. The manufacturing complexity and higher initial investment of the double helical gear shaft necessitate a strategic approach to its deployment. The decision to implement this advanced component ultimately hinges on a careful cost-benefit analysis. For high-horsepower, high-speed, and mission-critical systems, the long-term benefits of reduced maintenance, higher efficiency, and unparalleled reliability overwhelmingly justify the initial expense. Conversely, for simpler, lower-power machinery where cost is the primary driver, alternative gear types may be more pragmatic.

Therefore, understanding the distinct advantages and disadvantages of the double helical gear shaft empowers engineers and decision-makers to make informed choices. It is a powerful tool in the engineering arsenal, whose value is fully realized when its unique capabilities are perfectly matched to the application’s requirements.

Feel free to contact us for more information or assistance.

Our LinkedIn Page