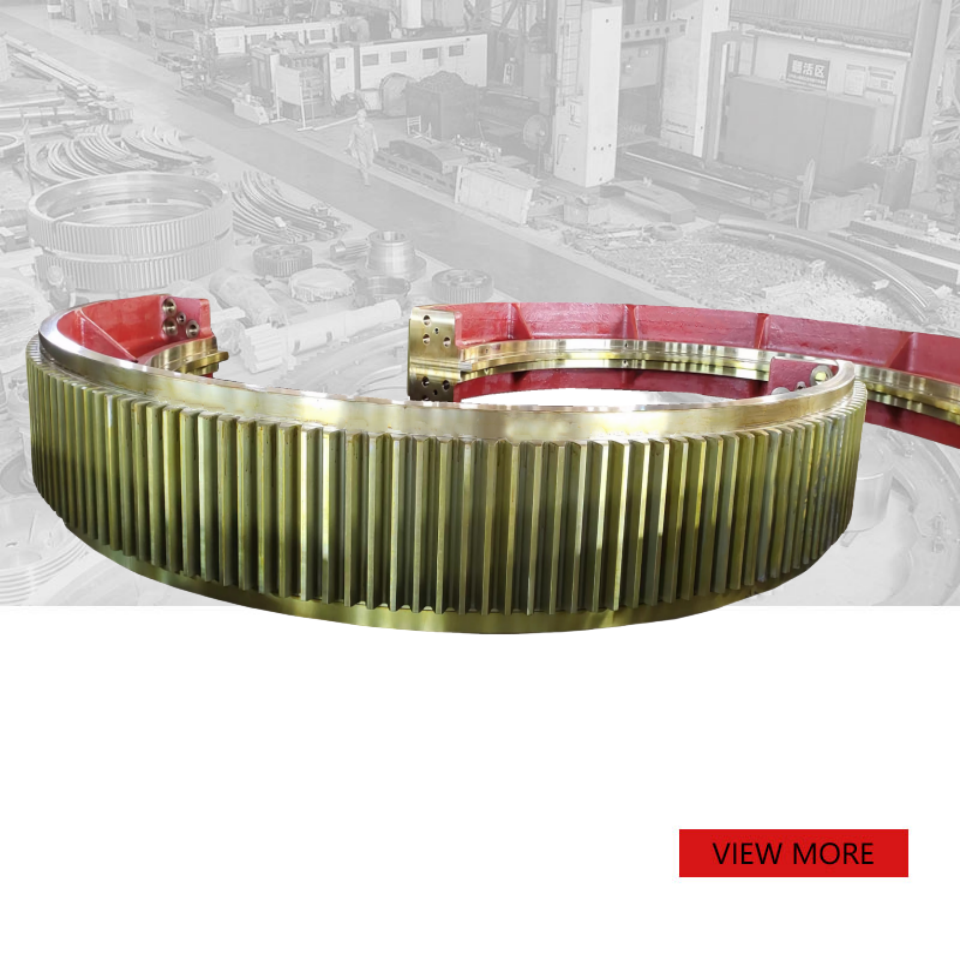

Non-standard customized rotary kiln casting gear ring

PRODUCT PARAMETERS

Description

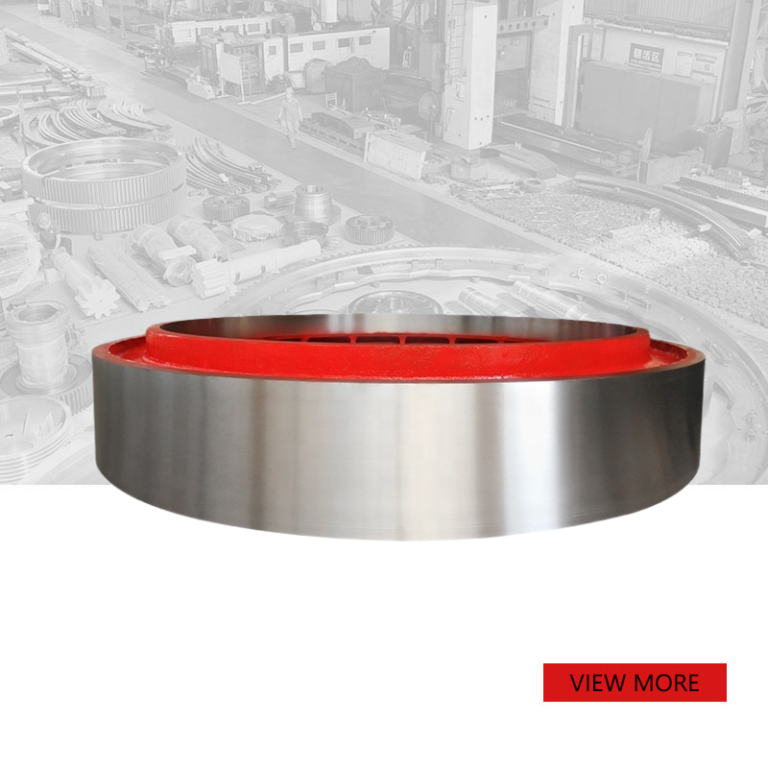

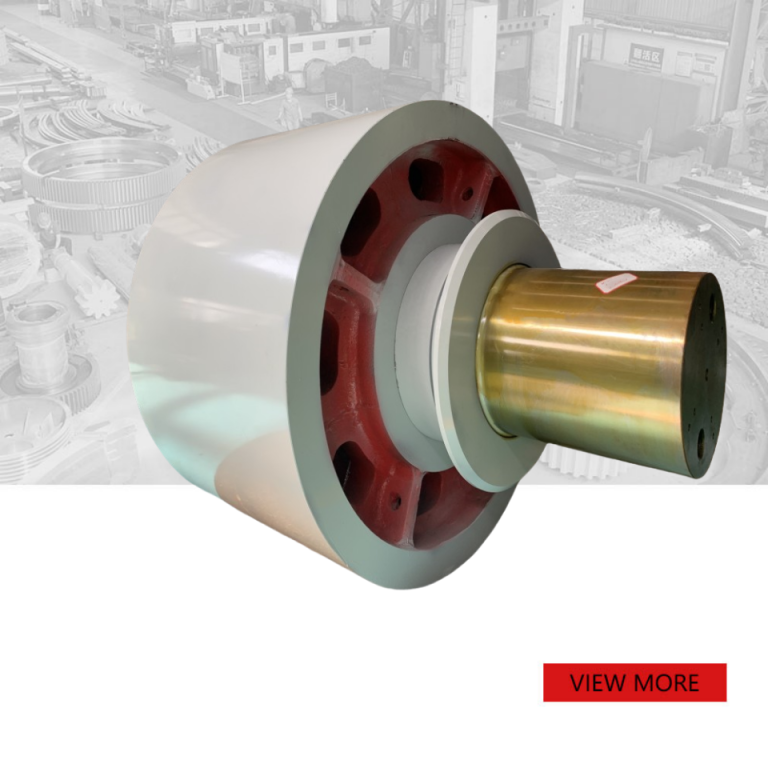

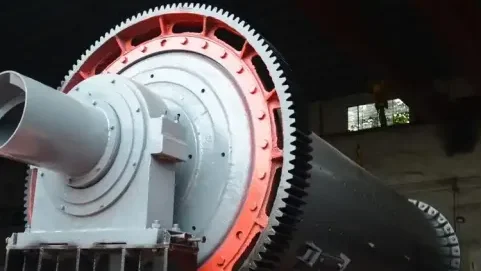

1. Overview of rotary kiln casting gear ring

The rotary kiln casting gear ring is one of the core components of the rotary kiln transmission system in industries such as cement and metallurgy. It transmits power to the rotary kiln body by meshing with the gear of the drive device to ensure its smooth rotation. The casting gear ring is usually made of high-strength alloy steel and can withstand high temperature and heavy load working environment. Good design and manufacturing process ensure the reliability and durability of the gear ring in long-term operation, which is of great significance for improving production efficiency and reducing maintenance costs.

2. Installation method and function

The installation of the rotary kiln casting gear ring needs to be strictly carried out in accordance with the instruction manual provided by the manufacturer, including positioning, calibration, fixing and other steps. Correct installation can not only ensure the precise fit between the gear ring and the drive gear, but also effectively reduce vibration and noise during operation. As the bridge of the transmission system, the main function of the casting gear ring is to achieve power transmission, and it can also play a role in adjusting the speed of the rotary kiln, thereby optimizing the entire production process.

3. Selection and requirements of materials for rotary kiln casting gear ring

The selection of suitable materials is crucial to ensure the performance of the casting gear ring. Commonly used materials include high manganese steel, chromium-molybdenum alloy steel and other special alloy steels.

Industry properties

| Profile | gear ring |

| Shape | helical,spur,straight |

| Material | Steel |

| Process | casting |

4. Application scenarios, common problems and maintenance

The rotary kiln casting gear ring is widely used in cement, mining, chemical industry and other fields, especially in large rotary kiln equipment. It plays an indispensable role. Common problems mainly include tooth surface wear and crack formation, which can usually be prevented by regular inspection and timely replacement of damaged parts. In order to extend the service life, it is recommended to establish a standardized daily maintenance system, such as regular cleaning of surface dirt, application of lubricating oil and other measures.

5.Production process

The production process of cast gear rings is a complex and delicate process, which usually includes the following main steps:

-Design and mold manufacturing:

Product design is carried out according to the drawings and technical requirements provided by the customer.

Make wooden or metal molds for subsequent sand molds or other types of molding.

-Melting and pouring:

The selected metal material is placed in an electric furnace or cupola for melting.

The mold is preheated before pouring to reduce the temperature difference.

The molten metal is poured into the prepared mold.

-Cleaning and polishing:

Remove attachments such as sand, oxide scale, etc. on the surface of the casting.

Polish the surface of the casting to make it smooth and reach the designed size.

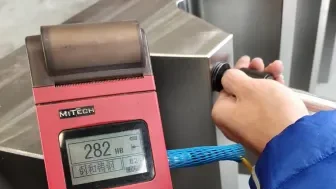

-Heat treatment:

Perform heat treatment processes such as quenching and tempering to increase the hardness and wear resistance of the gear ring and improve its mechanical properties.

– Finishing:

Roughing, semi-finishing and finishing of gears to ensure accurate tooth shape.

Including turning, hobbing, shaping, grinding and other processes.

-Testing and Inspection:

– Check the quality of castings, including dimensional accuracy, surface quality, hardness testing, flaw detection, etc.

6. Packaging

The materials of rotary kiln casting gear rings are sustainable and recyclable, with little impact on the environment.

We have more than 15 years of export experience, and we strive for excellence in packaging solutions and strive to adopt the most reasonable transportation methods and packaging solutions.

7.FAQs of casting gear ring

-How long is the delivery time? 65-100days

-What are the packaging methods? According to customer requirements, plywood boxes are generally used.

-Do you accept third-party inspection? Yes

Contact us